Semiconductor Materials: Key Takeaways

- Silicon is still the go-to material for most chips as it strikes the right balance between performance and price

- Germanium kicked off the semiconductor revolution, and it still plays a key role in infrared and high-speed RF devices

- GaAs, SiC, and GaN are redefining the edge of performance, powering 5G, EVs, aerospace, and high-frequency radar

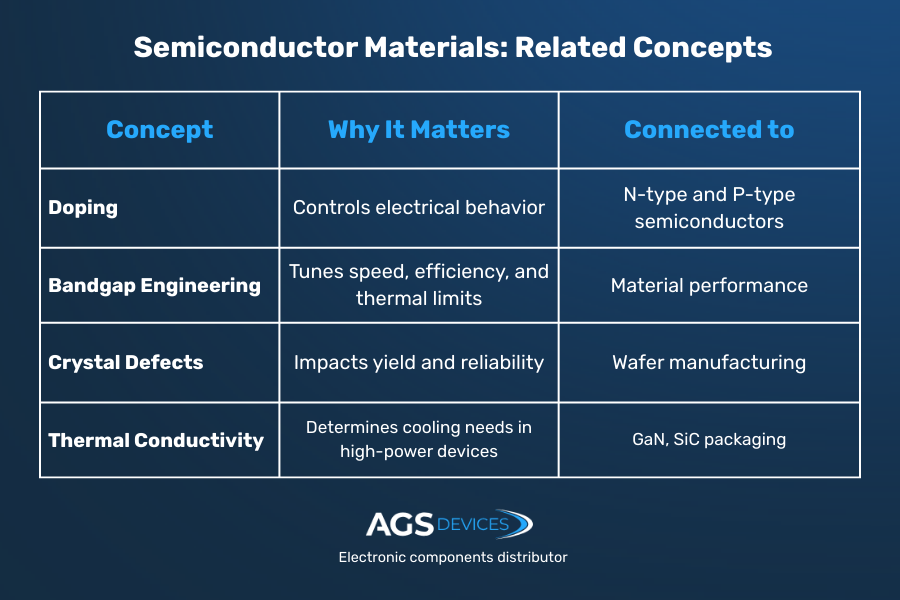

- Bandgap, mobility, and thermal behavior determine how a semiconductor performs and why material selection is never one-size-fits-all

- Next-gen electronics demand next-gen materials, and engineers are looking beyond silicon to push the limits & shortages of what chips can do

Silicon may rule the semiconductor world, but it’s not the only player in the game.

While it forms the heart of over 90% of all microchips, it’s just one member of a high-performing materials family that powers everything from smartphones to space systems.

As speed, power, and miniaturization push past what silicon can comfortably deliver, materials like germanium, gallium arsenide, and silicon carbide step in, each chosen for a job silicon wasn’t built to handle.

In this guide, we’ll explore:

- The most commonly used semiconductor materials

- Why silicon remains dominant and where it falls short

- How materials like GaAs and SiC are shaping high-performance electronics

- Real-world applications across computing, aerospace, and energy systems

Semiconductor Materials: Key Functions and Fundamentals

From logic chips to lasers, semiconductor materials are the foundation of modern electronics. Their unique ability to conduct electricity, but only under the right conditions, is what makes computing possible.

What Are Semiconductors Made Of?

Think of semiconductors as the gatekeepers of electricity, letting current through when needed, holding it back when not. They’re built from familiar elements: silicon, germanium, and exotic compounds like GaAs and SiC.

There are two primary types:

- Intrinsic semiconductors: Pure materials without impurities (like pure silicon)

- Extrinsic semiconductors: Doped with other elements (typically boron or phosphorus) to enhance conductivity

Curious how doping changes a semiconductor’s behavior? It all comes down to n-type and p-type conductivity, where electrons or holes carry the charge. We break down how each works in our guides to n-type semiconductors and p-type semiconductors, including real-world use cases and materials.

Why Semiconductor Materials Are Unique

What makes semiconductors so powerful is their flexibility. Their electrical properties can be tuned for specific tasks, and that’s not something metals or insulators can do.

- They occupy the middle ground between conductors and insulators

- Their conductivity can be precisely modified using semiconductor doping

- They’re essential to transistors, diodes, photodetectors, and laser systems

In short: semiconductor materials power the digital age, and the choice of material determines speed, efficiency, thermal tolerance, and reliability, which are all critical in today’s electronics landscape.

Why Silicon Dominates the Semiconductor Industry

When it comes to semiconductor materials, silicon is the undisputed heavyweight and for good reason. It’s abundant, it’s affordable, and it performs exceptionally well in most electronics.

Let’s break down why silicon leads and where it falls short.

1. Abundance and Affordability

You don’t have to dig far to find silicon. It’s in sand, in rocks, in the ground beneath your feet, second only to oxygen in abundance. And that abundance makes it not just cheap, but dependable.

Its natural availability gives it a huge cost advantage:

- It’s cheap to process in large volumes

- The infrastructure for silicon-based chip production is deeply mature

- Foundries, design tools, and supply chains are optimized around it

That’s why silicon became (and still remains) the foundation of the modern semiconductor industry.

2. Silicon’s Electrical Properties

Silicon doesn’t just win on cost; it performs well, too.

Its bandgap (~1.1 eV) is just right for switching applications, balancing speed with control. It also offers:

- High thermal stability, performing well in hot environments

- Low leakage current, crucial for power efficiency

These traits make silicon highly adaptable across consumer, industrial, and automotive sectors.

3. Modern Use Cases

Whether it’s guiding your GPS or scrolling through TikTok, chances are, silicon’s doing the heavy lifting.

It’s the quiet engine behind almost everything digital such as:

- CPUs and microcontrollers

- Power MOSFETs and IGBTs

- CMOS image sensors

- ASICs, SoCs, and memory chips

But it’s not perfect. As demand grows for high-frequency, high-voltage, or radiation-resistant performance, silicon starts to show its limits, paving the way for materials like GaN, SiC, and GaAs.

Applications in Electronics and Microchips

Each semiconductor material brings distinct performance advantages, and that’s why they show up in different corners of the electronics industry.

Here’s where they’re making the biggest impact:

- Power electronics: Silicon carbide (SiC) and gallium nitride (GaN) are now the go-to materials for EV inverters, industrial drives, and aerospace-grade power modules due to their high efficiency and thermal resilience

- High-speed communications: Gallium arsenide (GaAs) powers RF front ends, radar systems, and satellite communications thanks to its ultra-high electron mobility. Silicon-germanium (SiGe) blends speed and compatibility for 5G analog chips, radar, and low-noise amplifiers.

- General-purpose ICs: Silicon remains the standard for CMOS logic, SoCs, microcontrollers, and nearly all consumer electronics, thanks to its low cost and well-established manufacturing ecosystem.

- Optoelectronics and sensors: Germanium’s sensitivity to infrared makes it ideal for photodetectors and IR imaging. GaN also plays a role in LEDs, LiDAR systems, and laser diodes, especially in high-performance automotive and aerospace environments

Even the best semiconductor material can underperform if the packaging doesn’t match. The way a chip is packaged, its thermal interface, lead frame, and substrate can make or break power density, speed, and reliability.

Explore how semiconductor packaging factors into performance, especially in high-voltage and high-frequency environments.

Beyond Silicon: Germanium, GaAs, SiC, and Other Advanced Semiconductor Materials

While silicon dominates the global semiconductor landscape, it’s far from the only material shaping today’s electronics.

Germanium: The First Semiconductor Material

Germanium made history as the first true semiconductor, used in the world’s first transistor in 1947. But its thermal limitations eventually gave way to silicon.

Still, germanium hasn’t disappeared. In fact, it’s quietly thriving in niche, high-performance applications where speed and precision matter most.

Where it shines:

- Excellent carrier mobility for fast switching

- Used in optical sensors, infrared detectors, and photodiodes

- Forms SiGe (Silicon-Germanium) compounds for RF, 5G, and analog circuits

- Narrow bandgap: 0.66 eV

Gallium Arsenide (GaAs)

When speed and frequency come first, GaAs steps in. With its wider bandgap (1.42 eV) and exceptional electron mobility, it’s ideal for:

- Radar, satellite, and RF transceivers

- High-frequency amplifiers

- Optoelectronic devices like LEDs and laser diodes

Its downsides? GaAs is more brittle and expensive than silicon, limiting its use to specialized systems.

Silicon Carbide (SiC)

Built for extreme performance, SiC is changing the game in power electronics. It can handle higher voltages, faster switching speeds, and hotter temperatures than traditional silicon.

You’ll find SiC in:

- Electric vehicle inverters

- Aerospace propulsion systems

- High-voltage industrial converters

With an ultra-wide bandgap of ~3.2 eV, SiC minimizes switching losses and enables compact, high-efficiency designs.

Gallium Nitride (GaN)

GaN is fast, compact, and highly efficient: a rising star in next-gen semiconductor design.

Its high breakdown voltage and rapid switching make it perfect for:

- 5G infrastructure and RF front ends

- Fast chargers and compact power supplies

- Aerospace radar and avionics power systems

Fun fact: GaN and SiC are enabling 30–50% smaller power converters in EVs and satellites, boosting performance while saving space and energy.

Comparing Properties of Common Semiconductor Materials

Different applications call for different material properties. Choosing the right semiconductor starts with understanding how each one performs under real-world conditions.

From bandgap energy to thermal stability, here’s how the most common materials compare:

| Material | Bandgap (eV) | Mobility | Thermal Stability | Common Use |

| Silicon | 1.1 | Moderate | High | General-purpose ICs, CMOS, logic |

| Germanium | 0.66 | High | Low | Infrared optics, SiGe RF chips |

| GaAs | 1.42 | Very High | Moderate | RF transceivers, radar, satellites |

| SiC | 3.2 | Moderate | Very High | Power modules, EV inverters |

| GaN | 3.4 | High | High | 5G, aerospace radar, chargers |

Why Material Choice Matters and How AGS Devices Helps You Get It Right

From silicon’s universal utility to GaN’s high-frequency agility, the right semiconductor material is at the core of every high-performance device.

As demands rise for faster, smaller, and more energy-efficient electronics, engineers and sourcing teams must weigh conductivity, thermal behavior, and cost, material by material.

At AGS Devices, we help you plan beyond the datasheet with:

Certified and traceable semiconductor components

BOM support for material cross-referencing

Quality assurance backed by ISO and IDEA-certified inspection

In addition to semiconductors, we also provide electronic components such as:

Semiconductor Materials: FAQs

Before you dive deeper, let’s clear up some of the most common questions engineers and buyers ask.

What are semiconductor materials?

Semiconductor materials are elements or compounds with electrical conductivity between conductors and insulators, used to build chips, transistors, and diodes.

What are the most common semiconductor materials?

The most common materials include silicon, germanium, gallium arsenide (GaAs), silicon carbide (SiC), and gallium nitride (GaN).

Why is silicon the most used semiconductor material?

Silicon is abundant, it’s cost-effective, and it offers excellent electrical and thermal stability, making it ideal for mass production of ICs and microchips.

Where is gallium arsenide used in electronics?

GaAs is widely used in RF components, satellite systems, and high-speed communications due to its superior electron mobility.

How is silicon carbide different from silicon?

SiC handles higher voltages, temperatures, and switching speeds, making it ideal for power electronics in EVs and aerospace.

What is the role of germanium in semiconductors today?

Though replaced by silicon in most applications, germanium is still used in infrared sensors, photodetectors, and SiGe RF chips.

What are compound semiconductors?

Compound semiconductors are made from two or more elements (like GaAs or GaN) and are used in high-performance, high-frequency, or high-temperature environments.