Inductors play an important role in regulating current, storing energy, and filtering signals in many electronic devices.

The global passive components market, which inductors are a part of, is projected to reach $48.7 billion by 2027, driven by advancements in automotive, telecom, and many other industries.

But you should know that not all inductors are created the same and choosing the right type can impact reliability, efficiency and overall circuit performance.

Today, we’ll cover different types of inductors, explain how they work, and where they’re used the most across the most popular industries.

How Do Inductors Work?

Inductors are two-terminal electronic components that have an irreplaceable role in energy storage, signal filtering, and electromagnetic interference (EMI) suppression.

Inside, inductors consist of a coil of wire wound around a core material, typically air, ferrite, or iron.

When current flows through the coil, it generates a magnetic field that opposes sudden fluctuations in current, a property known as inductance.

Key Functions of Inductors in Electronics

- Energy storage: They store electrical energy in their magnetic field and release it when it’s necessary, making them essential for voltage regulation in power supplies.

- Filtering and signal processing: In circuits, they work alongside capacitors to filter out unwanted frequencies, providing stable and noise-free signal transmission.

- Electromagnetic interference (EMI) reduction: They are used in chokes and transformers to minimize interference in high-frequency circuits, particularly in automotive, aerospace, and telecommunications applications.

- Voltage stabilization: Many DC-DC converters and switching power supplies rely on inductors to regulate voltage and prevent power fluctuations in sensitive electronic systems.

Different Types of Inductors and Their Functions

The core material affects the inductor’s efficiency, making some more suitable for high-frequency circuits, while others are ideal for power regulation and energy storage.

The most common types of inductors include:

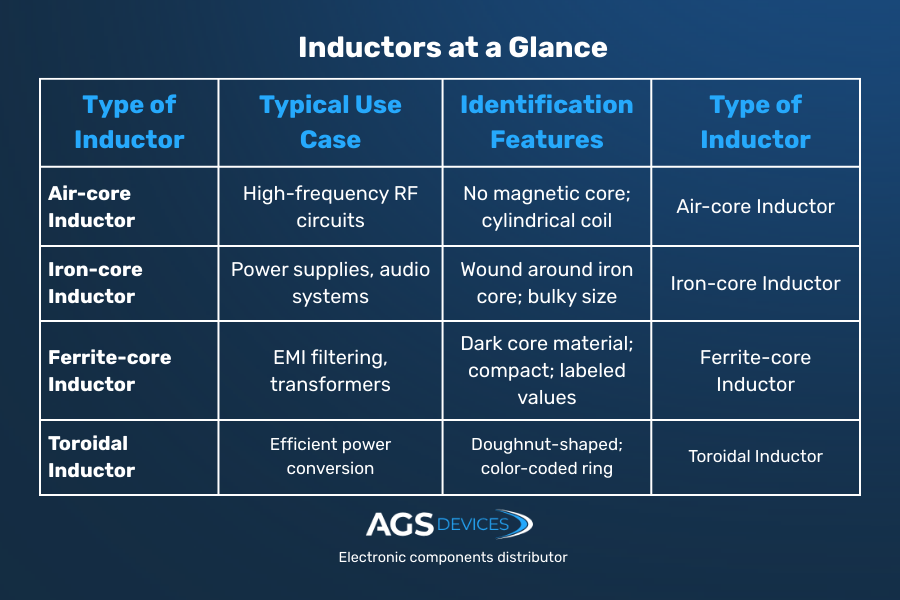

1. Air-Core Inductors

These inductors don’t use a magnetic core, meaning they rely purely on the coil’s structure to generate inductance.

If you’ve ever seen a wireless charging pad at a coffee shop, chances are it’s using an air-core inductor to create the magnetic field that transfers power to your phone.

Other common applications include:

- RF circuits and wireless communication systems due to their ability to handle high frequencies with minimal distortion.

- Radio antennas and high-speed data transmission systems.

- Wireless power transfer technologies, such as contactless charging pads for smartphones.

2. Iron-Core Inductors

These inductors use a solid iron or laminated steel core, allowing them to store larger amounts of energy and generate higher inductance values.

For example, the giant transformers powering your home use iron-core inductors to regulate voltage, ensuring stable power distribution across the electrical grid.

Other common applications include:

- Power transformers and industrial power supplies where large energy storage and transfer are needed.

- Audio processing circuits to maintain signal integrity in professional audio equipment.

- DC chokes in power conversion systems.

3. Ferrite-Core Inductors

Ferrite-core inductors use ferrite materials, a type of ceramic compound, to create high inductance with minimal energy loss.

Ever noticed a small cylindrical lump on your laptop charger cable? That’s a ferrite bead inductor, which blocks unwanted interference, ensuring your charger doesn’t introduce noise into your device.

Other common applications include:

- EMI filters for reducing electrical noise in consumer electronics, power supplies, and industrial automation systems.

- DC-DC converters found in automotive power electronics and renewable energy systems.

- RF applications like AM/FM radio receivers.

4. Toroidal Inductors

They feature a ring-shaped (donut-like) core, often made from ferrite or iron powder. The unique shape allows for higher efficiency, reduced electromagnetic interference (EMI), and compact design.

Next time you see a solar panel inverter, think of the toroidal inductors inside, helping convert solar energy into stable power for homes and businesses.

Other common applications include:

- High-power applications such as solar inverters and uninterruptible power supplies (UPS).

- High-efficiency audio amplifiers for signal smoothing.

- Medical imaging systems, where low EMI is crucial for accurate readings.

5. Variable Inductors

Variable inductors allow for adjustable inductance values, making them ideal for tuning circuits and frequency adjustments.

Your old-school radio tuner? It likely used a variable inductor to adjust the signal strength and lock onto your favorite station.

Other common applications include:

- Radio transmitters and receivers to fine-tune signal frequencies.

- Tunable antenna circuits for optimizing communication signal strength.

- Test and measurement equipment for calibration and circuit optimization.

Key Applications of Inductors in Various Industries

The role of inductors spans various industries and applications.

Key industries include:

1. Power Supply Systems

Inductors are crucial for power management, particularly in switching power supplies and voltage regulators. They help smooth out voltage fluctuations, store energy, and prevent electrical noise from disrupting circuits.

In power supply systems, they are used in:

- DC-DC converters in electric vehicles, industrial automation, and renewable energy systems.

- AC power filtering in power grids to stabilize voltage supply.

- Switching power supplies in computers and telecommunications equipment.

2. RF and Communication Circuits

In radio frequency (RF) and communication systems, inductors are used to tune frequencies, filter signals, and prevent interference. They work alongside capacitors to create resonant circuits that enhance signal clarity and strength.

In RF and communication circuits, they are used in:

- Wireless communication systems (Wi-Fi, Bluetooth, 5G networks).

- RF amplifiers in mobile devices, radios, and satellite communications.

- Tuning circuits in televisions, antennas, and radio transmitters.

3. Automotive and Aerospace

Automotive and aerospace industries demand rugged and high-performance inductors capable of handling extreme temperatures, vibrations, and power loads.

In automotive and aerospace industries, they are used in:

- Electric vehicles (EVs) and hybrid systems use inductors in battery management systems and regenerative braking.

- Advanced driver-assistance systems (ADAS), such as collision avoidance and adaptive cruise control, rely on inductors for stable power supply.

- Aerospace avionics and satellite communication systems use inductors for RF signal processing.

4. Inductors in Medical Devices

The medical industry depends on precision electronics, and inductors play a major role in signal filtering, power management, and RF communication for life-saving devices.

In the medical industry, they are used in:

- MRI machines and medical imaging systems use inductors to eliminate interference and enhance image clarity.

- Implantable medical devices, like pacemakers, use inductors in low-power circuits to ensure stable operation and longevity.

- Wearable health monitors rely on inductors for wireless charging and data transmission.

5. Industrial and Consumer Electronics Applications

From factory automation to everyday gadgets, inductors improve power efficiency, filter signals, and enhance battery life in electronic devices.

In the industrial and consumer electronic industry, they are used in:

- Smartphones, tablets, and laptops use inductors in power regulators, audio circuits, and RF modules.

- Home appliances, like microwaves and washing machines, rely on inductors for noise suppression and energy efficiency.

- Industrial robotics use inductors in motor controllers and power conversion systems.

Factors To Consider When Choosing the Right Inductor

Choosing the right inductor is essential for ensuring efficiency, stability, and performance in electronic circuits

- Core material & inductance value: Air-core inductors work best for high-frequency RF applications, while iron-core and ferrite-core inductors offer higher inductance for power regulation and EMI suppression.

- Current rating & resistance: Low-resistance inductors improve DC-DC converter efficiency, while high-current inductors are essential for automotive and industrial applications.

- Size & thermal performance: Compact inductors suit consumer electronics, but larger inductors handle high-power applications better by managing heat dissipation.

- Application-specific needs: High-frequency inductors support Wi-Fi and 5G, power inductors manage EV batteries and renewable energy, and shielded inductors prevent EMI in medical and aerospace systems.

Why Source High-Quality Inductors From AGS Devices?

At AGS Devices, we fully understand the important role inductors play in power efficiency, signal integrity, and long-term reliability in electronic systems.

We’re also completely aware that having the right inductor makes all the difference in performance.

With our guidelines and strict quality control measures, you can be sure that every component from AGS meets the demands of high-performance systems.

Beyond inductors, we supply a wide range of electronic components, including:

With a dedicated team and an unwavering commitment to on-time delivery, quality assurance, and expert support, AGS Devices is the trusted partner for engineers and manufacturers worldwide.