Capacitor Types & Applications: Key Points

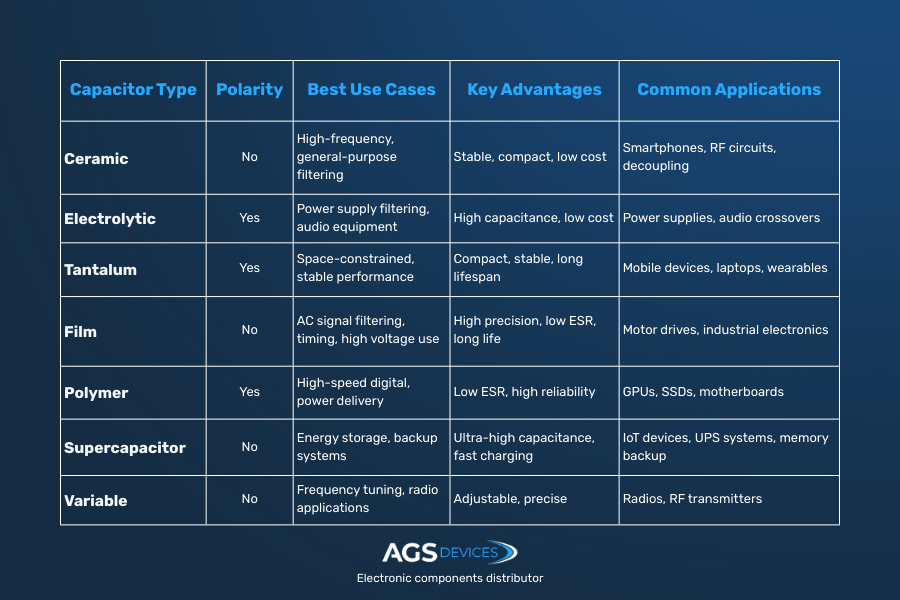

- Capacitor types include ceramic, electrolytic, film, tantalum, polymer, supercapacitors, and variable

- Each type is designed for specific applications like filtering, energy storage, or frequency tuning

- Capacitors regulate voltage, store energy, and filter signals in nearly every electronic device

- Advanced designs like graphene and flexible capacitors support fast charging, high power density, and wearable tech innovations

- Choosing the right capacitor depends on critical specs: capacitance, voltage rating, ESR, dielectric type, and tolerance

The global capacitor market is on track to reach $61.83 billion by 2032 — and for good reason.

Capacitors are essential in nearly every electronic device, from smartphones and EVs to medical equipment and industrial systems.

With so many capacitor types available, each designed for specific applications and performance needs, you need to know which one to choose.

In this guide, you’ll learn:

- The main types of capacitors and their applications

- Use cases across industries like automotive, medical, and telecom

- What advanced technologies like graphene and polymer capacitors bring to the table

- Which capacitor specs matter most and how to choose the right one

Different Types of Capacitors and Their Applications

Capacitors are passive components that come in many forms, each suited for specific applications, frequencies, voltage ranges, and environmental conditions.

Below is a breakdown of the most common types of capacitors, how they work, and where they’re used.

1. Ceramic Capacitors

Highly stable and non-polar, ceramic capacitors are the most widely used capacitor type for general-purpose and high-frequency applications.

- Common in coupling, decoupling, bypassing, and signal filtering circuits

- Found in RF modules, smartphones, laptops, and high-speed digital electronics

- Ideal for small-signal and high-frequency applications

- They are non-polarized and much easier to install

- Frequently compared in electrolytic vs. ceramic capacitor discussions for their precision and cost-effectiveness

2. Electrolytic Capacitors

Known for their high capacitance and polarized design, electrolytics are essential in circuits that need bulk energy storage or voltage smoothing.

- Used in power supply filtering, audio crossover networks, and timing circuits

- Found in LED drivers, amplifiers, and low-frequency signal applications

- Require attention to capacitor polarity, as the long leg is typically the positive terminal

- Often debated in ceramic vs. electrolytic capacitor comparisons for performance and longevity

3. Tantalum Capacitors

Compact and reliable, tantalum capacitors offer better stability and longer life than traditional electrolytics at a higher cost.

- Popular in compact electronics like smartphones, tablets, and medical device

- Provide stable capacitance and low leakage over time

- Always polarized, observe capacitor anode and cathode orientation during installation

- Frequently mentioned in tantalum vs. ceramic capacitor evaluations for space-saving benefits

4. Film Capacitors

Built with a thin plastic dielectric, film capacitors offer excellent electrical properties, low ESR, and long-term reliability.

- Found in power supplies, motor drives, audio systems, and various types of circuits

- Used in high-frequency and high-stability circuits

- Durable, with excellent tolerance and performance across a wide temperature range

- Often compared in film capacitor vs. ceramic and film capacitor vs. electrolytic performance studies

5. Polymer Capacitors

An improved version of electrolytics, these use a solid polymer electrolyte for better conductivity and low ESR.

- Best suited for digital high-speed circuits, power management modules, and GPUs

- Provide higher ripple current handling and longer lifespan

- Chosen for applications where low ESR and compact size are critical

- Found in gaming consoles, SSDs, and high-end motherboards

6. Super Capacitors (Ultracapacitors)

These capacitors offer extremely high capacitance values and are ideal for applications requiring rapid energy storage and discharge.

- Used in energy harvesting systems, regenerative braking in EVs, and backup systems

- Capable of charging and discharging in seconds

- Bridge the gap between traditional capacitors and batteries

- Integral in renewable energy grids and memory protection circuits

7. Variable Capacitors

Allow users to manually adjust capacitance which is essential in tuning and frequency adjustment applications.

- Found in radio transmitters, vintage radios, and RF signal circuits

- Used in oscillators, frequency modulators, and tuning filters

- Categorized under variable capacitor types, including trimmer and padder capacitors

- Provide dynamic control not found in fixed capacitors

How to Choose the Right Capacitor

When choosing the right capacitor, consider the following:

- Capacitance value: The capacitance value is critical as it determines the amount of electric charge the capacitor can store. Selecting the appropriate capacitance is key to ensure it meets the circuit’s functional requirements.

- Voltage rating: The voltage rating is important because it ensures the capacitor can safely handle the highest voltage applied without risking damage or failure.

- Dielectric type: The type of dielectric used in a capacitor affects its temperature stability, frequency response, and physical size, making it a crucial factor based on the specific needs of the application.

- Physical size and form factor: The physical size and form of the capacitor should be considered to ensure it fits within the spatial constraints of your design.

- Temperature range: Selecting a capacitor that can operate within the environmental temperature extremes of your application is essential for reliable performance.

- Equivalent series resistance (ESR): A lower ESR is beneficial in high-frequency applications as it reduces heat generation and improves overall efficiency.

- Tolerance: The tolerance of a capacitor indicates how much the actual capacitance can vary from its rated value, which is important for circuits where precision is key.

- Leakage current: A lower leakage current is important in applications where the capacitor needs to maintain its charge for extended periods, such as in timing or memory retention circuits.

Advanced Capacitor Technologies

Exploring the forefront of capacitor technology reveals a range of innovative designs, each tailored to meet specific modern demands.

These advanced capacitors are shaping the future of electronic components:

- Graphene capacitors: Graphene capacitors exhibit extremely high conductivity and thermal performance. They are advancing in areas like energy storage and quick-charging applications due to their superior charge/discharge rates.

- Solid-state capacitors: Solid-state capacitors are known for their improved reliability and stability, as they are increasingly used in high-density applications like advanced computing and mobile devices where space and performance are crucial.

- Nanostructured capacitors: With increased surface area at the nanoscale, nanostructured capacitors offer enhanced capacitance and efficiency. They’re pivotal in miniaturized electronics and advanced energy storage solutions.

- Flexible capacitors: Flexible capacitors are essential in wearable electronics and foldable devices, offering adaptability in design without compromising capacitance.

- High-temperature capacitors: High temperature capacitors can operate in extreme temperatures. They are crucial in automotive, aerospace, and industrial applications where environmental conditions are harsh.

- Low-ESR capacitors: Low-ESR capacitors minimize energy loss and heat generation, making them ideal for high-frequency applications. These high-frequency applications include power supplies in computing and telecommunications equipment.

Capacitor Selection: Key Takeaways

- The right capacitor type depends on whether you need filtering, timing, energy storage, or signal processing.

- Always match voltage rating, capacitance value, ESR, and dielectric to your design requirements.

- Use cases for graphene and solid-state capacitors are expanding rapidly in EVs, wearables, and

- Solid-state polymer and tantalum capacitors often outperform traditional electrolytic types in harsh conditions.

AGS Devices: A Trusted Distributor of Capacitors

AGS Devices specializes in the distribution of high-quality capacitors, ensuring each product meets stringent standards. Our comprehensive quality control system ensures authenticity and high-performance standards required in various applications.

We also distribute electronic components such as:

- Power Supply Distributors

- Semiconductors for Sale

- Optoelectronics

- Circuit Protection

- Interconnects

- Passive Components Electronics

- Electronic Testing Equipment

- Electromechanical Devices

We are dedicated to supplying capacitors that are reliable and durable. The team at AGS understands the critical role capacitors play in electronic circuits, and we have many procedures in place to ensure that every component we distribute contributes to the optimal functioning of your projects.

As a leading distributor of capacitors, our goal is to boost the efficiency and reliability of your supply chain.

committed to delivering quality components.

FAQs About Capacitor Types

Still have questions about capacitors? Here is some additional information about capacitors and capacitor types you might find useful.

What are capacitors?

Capacitors are electronic components that store and release electrical energy. They consist of two conductive plates separated by an insulating material called a dielectric.

When voltage is applied across the plates, it creates an electric field across the dielectric, allowing the capacitor to store energy. This stored energy can be released back into the circuit when needed.

Capacitors are essential in various electronic applications, including filtering, smoothing out electrical signals, and energy storage in power systems. Their capacity to store electrical charge is measured in farads.

How do you identify a capacitor?

You can identify a capacitor by examining its physical characteristics. Capacitors typically have markings that indicate their capacitance value (often in microfarads, µF), voltage rating, and sometimes the type (e.g., ceramic, electrolytic).

The physical size and shape (cylindrical, disc, rectangular) can also give clues about its type. In some cases, color coding or additional alphanumeric codes might be used to provide further details.

What is COG or NPO type capacitors?

COG or NPO type capacitors are a specific category of ceramic capacitors. COG stands for “Ceramic 0 temperature coefficient,” and NPO is an abbreviation derived from the materials used (Neodymium, Porcelain, and Oxygen).

What is the most durable type of capacitor?

The most durable type of capacitor is typically considered the solid-state type, which includes tantalum and polymer capacitors. These capacitors are known for their robustness, long-term reliability, and stability under various environmental conditions.

Can I use ceramic capacitors instead of polyester?

Yes, but it depends on the application. Ceramic capacitors are smaller and more temperature-stable, but they may have lower voltage ratings and non-linear behavior. Polyester capacitors offer better voltage tolerance and are better for circuits needing larger, more stable capacitance.