BOM Inventory Management: Key Takeaways

- Poor BOM alignment causes frequent supply chain disruptions because 60% of manufacturers rely on consistent component data

- Precise BOM inventory management helps with future planning, which helps organizations avoid costly extra purchases and warehouse overflow

- Linking your BOM to inventory software improves tracing parts and lifecycle visibility, which reduces the risk of sourcing obsolete components and mitigating EOL-related delays

- Companies that centralize BOM and inventory workflows report up to 40% faster production cycles, which improves collaboration and results in fewer material-related bottlenecks

- Strategic BOM management transforms procurement from reactive to proactive, as it predicts material shortages, maintains compliance, and chain, keeping the supply chain flexible and responsive.

Did you know that inaccurate BOMs contribute to over 80% of inventory-related production delays in manufacturing?

When your bill of materials (BOM) isn’t correctly aligned with inventory systems, it can lead to stockouts, overages, wasted materials, and costly production interruptions.

This is why BOM inventory management goes beyond record-keeping; it’s a strategic tool for reducing risk, improving accuracy, and keeping your supply chain running smoothly.

Today, you will learn:

- What BOM inventory management is and why it’s a key to better production planning

- The challenges of BOMs and poor inventory visibility

- Most important benefits of BOM inventory management

- Best practices to prevent material shortages and excess stock

BOM Alignment: The Key to Better Inventory Planning

Inventory issues don’t start in the warehouse; they usually begin on the BOM.

A good bill of materials (BOM) forms the backbone of accurate procurement, material forecasting, and production readiness.

BOM is extremely important for your business because:

- The BOM initiates purchasing decisions: If quantities, part numbers, or approved vendors are incorrect or outdated, your procurement team will order the wrong parts, or not enough of the right ones

- Inventory visibility starts with structure: Without a clean BOM, it’s challenging to know what’s truly needed vs. what’s already available in the inventory

- Errors multiply downstream: A single discrepancy in the BOM can trigger stockouts, delays in production, and emergency last-minute sourcing

To prevent these issues, your BOM alignment should include:

- Part numbers and descriptions that match across all systems

- Quantities that reflect real-world production usage

- Lifecycle data is always tracked and flagged (e.g., EOL or NRND components)

- Approved vendors that are linked directly to each part

- BOM data flows into inventory, ERP, and procurement platforms in real time

Benefits of Precise BOM Inventory Management

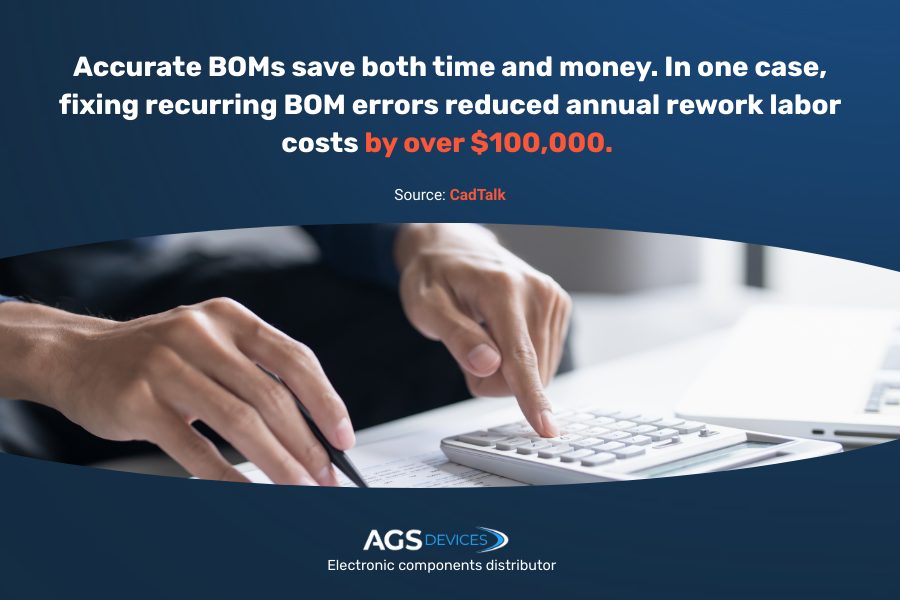

When BOM data is structured, current, and aligned with inventory systems, it becomes more than an engineering tool. It drives operational efficiency, BOM cost control, and production resilience.

Now, we will explain to you BOM inventory management across key areas in more detail.

1. Improves Forecasting and Procurement Accuracy

A clean BOM enables predictive procurement strategies based on actual production needs, not assumptions.

It supports future planning because it:

- Synchronizes part-level data with MRP/ERP systems to generate more accurate material requirement forecasts

- Enables procurement teams to preemptively address long lead-time components and sourcing constraints

- Reduces emergency spot buys caused by missing or misidentified parts during procurement cycles

2. Causes Fewer Stockouts and Overages

With real-time BOM and inventory alignment, businesses can move from reactive to proactive inventory management.

Some of the operational benefits include:

- Increased stock level visibility against BOM demand to avoid both under- and over-ordering

- Smarter replenishment logic that accounts for build frequency, batch size, and inventory turnover

- Reduced excess low-velocity or obsolete parts that inflate storage and holding costs

3. Speeds Up Production Cycles and Reduces Downtime

When the BOM mirrors what’s on the production floor, teams can reliably prepare the right materials for every production run. The faster production cycle results in:

- Streamlined work orders and production scheduling with fewer last-minute part substitutions

- Elimination of bottlenecks tied to incorrect or missing components

- Improved coordination across procurement, warehouse, and manufacturing for just-in-time availability

4. Provides Stronger Cross-Functional Collaboration

An accurate BOM keeps all teams working from the same data.

The collaborative advantages include:

- Standardized part definitions and data fields that reduce miscommunication across teams

- Clear revision control that makes sure all departments are referencing the same component version

- Tighter integration between product design, supply chain, and quality control functions

5. Enhances Compliance and Lifecycle Risk Management

With accurate BOM inventory tracking, companies can better manage regulatory obligations and component lifecycles.

Strategic outcomes of this include:

- Faster detection of components flagged as RoHS, REACH, or conflict-mineral non-compliant

- Early identification of end-of-life or NRND parts to enable redesign or sourcing alternatives

- Centralized audit documentation to support traceability, certifications, and industry compliance audits

Did you know? Inaccurate or unaligned MBOMs are among the top 3 causes of component shortages and unplanned downtime in electronics manufacturing.

Bill of Materials in Supply Chain Management

The bill of materials (BOM) serves as a data source that drives decisions throughout the entire supply chain process, from forecasting and procurement to inventory planning and fulfillment.

The BOM fits into the supply chain because it provides:

- Forecasting and demand planning: Accurate BOMs help procurement teams forecast part requirements based on real production needs

- Supplier and lead time alignment: Each component in the BOM can be linked to an approved vendor and expected lead time, helping teams plan purchases proactively

- Inventory accuracy and availability: The BOM defines what is needed for the production cycle, while the inventory system tracks what is in stock

- Production scheduling and capacity planning: A complete and accurate BOM ensures that production lines are not delayed by missing materials or last-minute sourcing

- Compliance and lifecycle control: BOMs that include part status and lifecycle data help teams avoid purchasing obsolete or non-compliant component

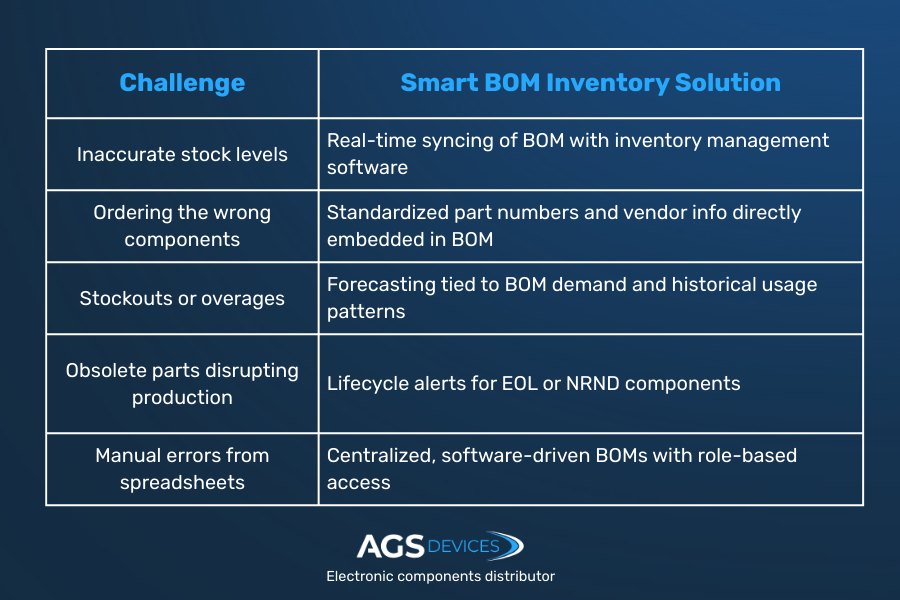

BOM Inventory Management Challenges and Risks

Even the most sophisticated supply chains can be delayed by a misaligned or outdated bill of materials.

Below are some of the most common issues companies face, along with the specific risks they create across operations.

Inaccurate or Outdated BOM Data

When your BOM does not reflect real-time requirements, materials planning becomes unreliable.

This often leads to cascading problems such as:

- Ordering incorrect quantities or outdated components

- Missing or mismatched part numbers between BOM and inventory systems

- Inability to track alternates or approved vendor options

Disconnected Systems and Spreadsheets

Many companies still manage BOMs and inventory in siloed systems or manual spreadsheets.

This creates friction across departments and results in:

- Double entry of part data and a higher chance of manual errors

- No automated alerts for EOL (End of Life) or lifecycle changes

- Difficulty identifying shortages before they impact production

Lack of Lifecycle and Compliance Visibility

Without clear lifecycle status and compliance data tied to your BOM, you risk introducing components that are obsolete or non-compliant.

Because of this, you might experience:

- Parts that break mid-production without warning

- Regulatory violations due to untracked RoHS or REACH status

- Unexpected redesigns to replace discontinued components

Stockouts, Overages, and Inventory Waste

When BOMs are not aligned with inventory planning, the consequences are felt immediately on the shop floor and in the warehouse.

This can easily cause:

- Stockouts caused by under-forecasting or missed reorders

- Overstock of unused components that consume unnecessary capital

- Inability to match current stock levels to real production needs

Learn How To Manage BOM With AGS Devices

When BOM discrepancies lead to stockouts or excess inventory, production grinds to a halt and costs rise.

Just like AGS Devices’ BOM management services validate components faster with tailored tools and expert procurement support, effective BOM–inventory alignment empowers you to optimize materials, reduce delays, and improve financial outcomes.

Here’s what we can create together:

- Simple integration: Just as AGS imports BOM files into a verification-ready platform, aligned processes ensure that your materials data flows accurately from engineering into operations.

- Supply assurance: Leveraging proactive planning techniques like advanced purchasing and buffer stocking (a core part of AGS’s strategy) helps you weather shortages with confidence

- Constant support: When lifecycle or supply disruptions arise, centralized BOM systems, backed by expert oversight, provide the visibility and agility to respond quickly, maintain throughput, and avoid costly surprises

In addition to robust BOM support, we also offer:

BOM Inventory Management: FAQs

If we haven’t answered all your questions above, here are some common questions you might be asking yourself.

What is the purpose of a bill of materials in inventory management?

The bill of materials (BOM) outlines all electronic components needed to build a product. When they are properly connected with inventory systems, it helps ensure the correct parts are ordered in the right quantities, which reduces the risk of stockouts or overages.

What is BOM inventory management?

BOM inventory management refers to the process of aligning your bill of materials with real-time inventory data. This ensures that material requirements are accurately reflected in procurement and stock levels, helping prevent production delays.

How does BOM fit into supply chain management?

In supply chain management, the BOM acts as a central planning document. It connects product design with procurement, logistics, and production, ensuring material availability and traceability across the supply chain.

What are the risks of not syncing BOMs with inventory systems?

When BOMs are not integrated with inventory management software, it can result in inaccurate stock data, missed reorders, over-purchasing, and unexpected production stoppages, especially when demand shifts or parts go to end-of-life.

Can inventory management software work with BOMs?

Yes. Most modern inventory BOM management software platforms include features specifically for managing BOMs, such as version control, part tracking, supplier integration, and lifecycle alerts.

What’s the difference between BOM inventory and general inventory?

General inventory tracks all items on hand, while BOM (Bill of Materials) inventory refers specifically to the components required for a particular product or build. BOM inventory ensures that what’s in stock aligns directly with active production needs.

How often should BOMs be updated in inventory systems?

BOMs should be reviewed regularly, ideally during every engineering change, before large production runs, or any time supplier or part status changes. Automating updates via integrated software can reduce errors and manual workload.