Avionics Components: Key Takeaways

- There’s no room for error in the sky. Whether it’s a flight control unit or a cockpit screen, every component has a job to do, and it must do it flawlessly, even at 38,000 feet

- These systems don’t operate in isolation. Like the members of a seasoned flight crew, they rely on constant communication to keep everything running smoothly

- Today’s glass cockpits aren’t just about aesthetics. They’re designed to reduce pilot stress and improve awareness, especially during critical tasks like takeoff and landing

- Integration is an art and a science. Standards like DO-254 and ARINC 661 exist for a reason; getting it wrong can ground an aircraft

- Built-in redundancy isn’t a luxury. It’s how aircraft stay in the sky when things go wrong

- At AGS Devices, we don’t just source components, we help keep your fleet flying.

A modern commercial aircraft flies with over 150 avionics components onboard, each one silently doing its job every second, without fail.

They’re not flashy. You won’t see them on a seatback screen or during takeoff. But without them?

No navigation. No communication. No flight.

From rugged flight control hardware to touchscreen displays and lightning-fast electronics, these systems make up the digital nervous system of the aircraft.

And in aviation, performance isn’t just nice to have. It’s a necessity.

In this guide, we’ll unpack the essential components behind today’s avionics:

- How hardware, displays, and electronics stay in sync

- Why integration and certification are non-negotiable

- What sourcing mistakes can cost you and how to avoid them

Avionics Components: Key Functions & System Roles

Avionics systems are the digital nervous system of any aircraft, managing everything from navigation to pilot displays and automated flight control.

At their core, avionics manage several major flight domains:

- Communication: VHF/UHF radios, SATCOM, datalinks

- Navigation: GPS, INS, air data systems

- Surveillance: ADS-B, radar, transponders

- Flight control: Autopilot, fly-by-wire, stability augmentation

- Monitoring & diagnostics: Engine and system health

- Display & interface: Cockpit instrumentation and pilot control

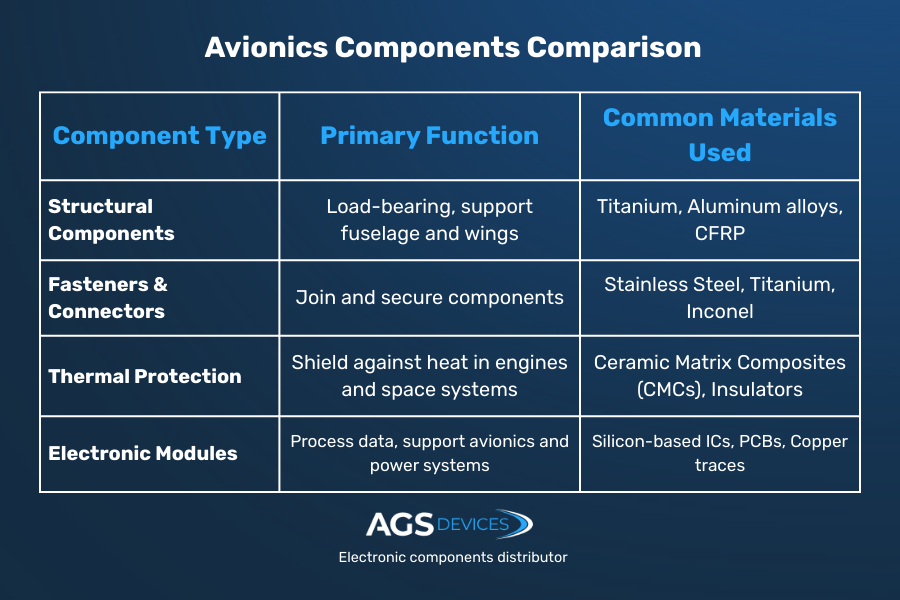

To simplify their complexity, avionics components are typically grouped into three main categories we’ll explore in this guide:

- Avionics hardware: Power units, control computers, data buses, and I/O modules

- Display systems & human-machine interfaces (HMI): Glass cockpits, HUDs, MFDs, control panels

- Avionics electronics & signal processing: Core logic, real-time processing, embedded systems, and routing

While avionics systems rely on complex computing and integration, it all begins with the semiconductors at the heart of every chip. Learn how Learn how semiconductors enable modern electronics.

Inside the Core: Hardware, Displays & Electronics That Power Avionics

Avionics systems may seem invisible to passengers, but they’re the silent network keeping aircraft safe, stable, and smart.

Let’s dive into the three pillars of modern avionics systems:

Avionics Hardware Systems

Hardware forms the ruggedized foundation of onboard avionics, designed to operate flawlessly in extreme environments while supporting real-time system functionality.

Key systems include:

- Flight control computers (FCCs): These handle autopilot, stability augmentation, and input/output processing for flight surfaces.

- Line-replaceable units (LRUs): Modular electronic units that can be swapped quickly on the ground or even in flight, depending on the system

- Power distribution & sensors: INUs and air data computers provide critical flight info, powered by aircraft-standard 115V AC and 28V DC lines

Did you know? Some commercial aircraft use over 1,000 LRUs, and select models allow hot-swapping to reduce downtime during maintenance.

Cockpit Displays & Human-Machine Interfaces (HMI)

Gone are the days of analog dials. Today’s cockpits are digital ecosystems, built for visibility, control, and pilot workload reduction, all through modern display systems.

Systems transforming flight decks:

- Primary & multifunction displays (PFDs/MFDs): These replace clusters of instruments with clean, centralized digital readouts

- Heads-up displays (HUDs): Project flight-critical data directly into the pilot’s line of sight, no head tilt required

- Touchscreen & keyboard inputs: Interactive control panels streamline workflows and are often based on standards like ARINC 661

You probably didn’t know this: Research comparing traditional analog cockpits and glass cockpit interfaces found that modern integrated flight displays (like Garmin G1000 glass panels) significantly reduced mental workload and improved situational awareness among pilots compared with older steam-gauge panels in simulation tests.

Avionics Electronics & Signal Processing

Behind every smart display and control panel is a dense network of high-speed processors, converters, and buses moving data at lightning speed, with redundancy built in.

Here’s what’s working behind the screens:

- Signal processing & converters: Translate analog sensor inputs into digital outputs used across systems.

- Data buses & protocols: From ARINC 429 to Ethernet, these allow subsystems to communicate and react in real time.

- Computing cores: Redundant processors and DFDAUs ensure fault tolerance and continuous data logging for post-flight analysis

Advanced avionics processors are fabricated using N-type and P-type semiconductors, which control current flow across critical avionics systems. Learn how N-type and P-type semiconductors operate at the atomic level.

Fun fact: Ever wondered how much wiring goes into a modern jet like the 787? Try over 60 miles, most of it just to handle the aircraft’s avionics. It’s more than just wires; it’s a lifeline.

How Avionics Components Work Together

Avionics components don’t operate in isolation. They form a tightly coordinated network where data flows continuously between sensors, processors, displays, and control systems.

How the Integration Network Functions

Modern avionics rely on high-speed communication pathways known as data buses. These buses act like information highways that connect discrete systems, enabling real-time data sharing and ensuring synchronized operations across flight control, navigation, communication, and cockpit interfaces.

- Shared bus architecture: Standards such as ARINC 429 and MIL-STD-1553 provide reliable links between components. These protocols define how messages are formatted, sent, and interpreted across avionics subsystems.

- Time-synchronized data systems: Deterministic communication is essential, meaning data arrives on schedule and in predictable order. Time synchronization ensures that navigation sensors, flight control computers, and displays are all operating from the same “clock.”

- Example end-to-end flow: Navigation sensors (GPS/INS) feed attitude and position into the flight control computer. That data is then routed via ARINC/MIL-STD buses to cockpit displays and autothrottle/autopilot systems so the aircraft maintains its intended flight path.

Why Integration Matters

- Real-time awareness: Integrated systems give pilots a unified situational picture, replacing fragmented displays with consolidated, accurate flight data.

- Safety and redundancy: With multiple paths and standardized communication, systems can continue functioning even if one component fails

- Upgradability: Standards-based integration enables easier upgrades and modular replacements without re-architecting the entire avionics suite, a key factor for reducing lifecycle costs

Sure, integration sounds technical, but in practice, it’s what keeps everything talking to each other when it really matters.

How AGS Devices Supports Avionics Component Sourcing

In the high-stakes world of aerospace, avionics components must meet the highest standards of performance, reliability, and traceability.

That’s where AGS Devices steps in, not just as a supplier, but as a sourcing partner trusted by engineers, MROs, and OEMs worldwide.

We support your programs with:

- End-to-end traceability and documentation: Every part is backed by verifiable data: manufacturer certifications, test reports, and compliance records, critical for airworthiness and regulatory audits

- Obsolescence and shortage solutions: Struggling with last-time buys or long lead times? We track EOL notices, find alternates, and help future-proof your avionics supply chain

- Custom kitting and BOM optimization: Save time with pre-bundled, fully labeled kits. We streamline complex procurement into a single, flight-ready delivery, reducing downtime and integration risk

Given the ongoing impact of global semiconductor shortages, sourcing delays remain one of the top concerns for aerospace teams. Explore the root causes and impacts of the semiconductor crisis.

We also support your full component sourcing needs, offering:

Avionics Components: FAQs

Still have questions about what powers the brains of an aircraft? Below, we answer the most common questions engineers, buyers, and aviation professionals ask about avionics components.

What are the most common avionics components?

Common components include flight control computers, inertial navigation units (INUs), cockpit displays, air data sensors, radios, and power distribution modules.

What is the difference between avionics hardware and electronics?

Avionics hardware refers to the physical units (like LRUs or control panels), while electronics refers to the internal circuitry that enables processing, communication, and signal conversion.

What are glass cockpit avionics?

Glass cockpit avionics replace analog gauges with high-resolution digital displays like PFDs and MFDs, improving situational awareness and system integration.

How are avionics components certified for use?

Components undergo rigorous testing and must comply with standards like DO-178C (software), DO-254 (hardware), and ARINC/MIL-STD protocols to be approved for aerospace use.

How can AGS Devices help with avionics supply chain issues?

AGS Devices sources certified, traceable avionics components and helps teams manage obsolescence, lead time risks, and shortage mitigation with custom kitting and BOM support.

What are line-replaceable units (LRUs) in avionics?

LRUs are modular avionics components designed to be quickly swapped out on the flight line, minimizing downtime and simplifying maintenance.

Why is data bus architecture important in avionics systems?

Data buses like ARINC 429 or MIL-STD-1553 ensure reliable, real-time communication between critical systems, essential for synchronized flight operations and system interoperability.