Obsolescence Management: Key Takeaways

- A proactive process to track, assess, and mitigate the risks of end-of-life components within supply chains

- Shrinking component lifecycles and growing global demand are making obsolescence a top-tier supply chain concern, especially in regulated industries

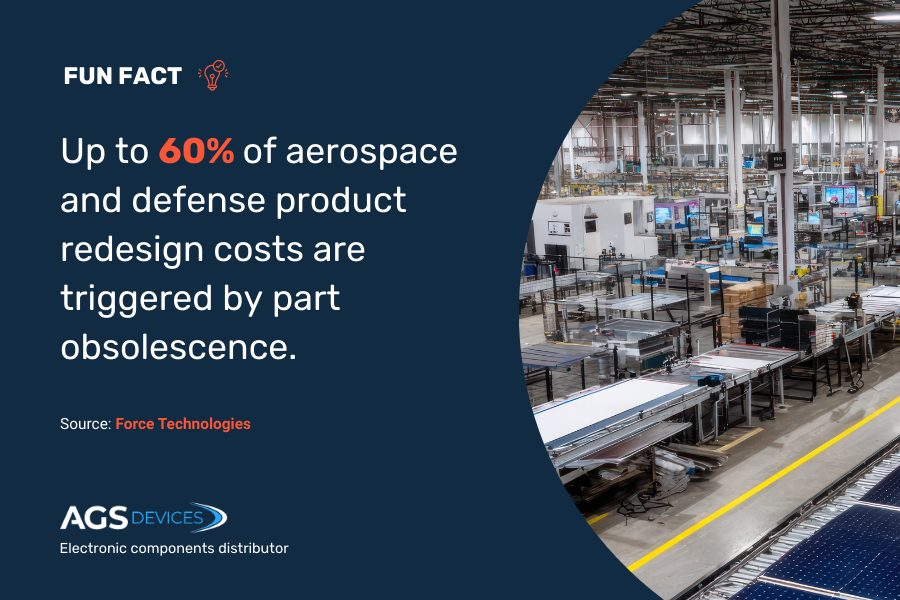

- Aerospace, defense, medical, and industrial sectors often rely on long product lifecycles that don’t match modern component turnover rates

- Ignoring EOL risks can lead to sourcing delays, counterfeit parts, regulatory issues, and full-scale product redesigns

- Ask most engineering teams about obsolescence, and you’ll probably get a shrug until a production run grinds to a halt. By then, the fix usually comes with a painful price tag, and obsolescence management is about avoiding that “fire drill” moment altogether

- From real-time part verification to sourcing obsolete components and building custom obsolescence plans, AGS helps manufacturers stay ahead of risk, not react to it

Over 470,000 components reached end-of-life (EOL) status in 2023, disrupting production across industries from aerospace to medical devices.

For OEMs, manufacturers, and supply chain managers, component obsolescence is no longer a rare challenge; it’s a constant operational risk.

As product lifecycles shrink and sourcing grows more complex, companies must proactively manage EOL risks or face costly delays, compliance issues, and forced redesigns.

That’s where obsolescence management comes in, not just as a sourcing tactic, but as a strategic defense for business continuity.

In this guide, we’ll cover:

- Why obsolescence management is critical for modern supply chains

- The real risks of ignoring end-of-life (EOL) components

- Steps to build an effective obsolescence management plan

- Best practices to secure alternates and avoid last-minute redesigns

What Obsolescence Management Actually Solves

Most product teams don’t think about obsolete components until the production line stalls or redesign costs hit six figures. Obsolescence management isn’t just a nice-to-have; it’s a critical supply chain safeguard.

It’s the process of planning for, identifying, and mitigating the risks associated with end-of-life (EOL) components, ensuring that you don’t lose time, compliance, or budget when parts go dark.

What it helps you do:

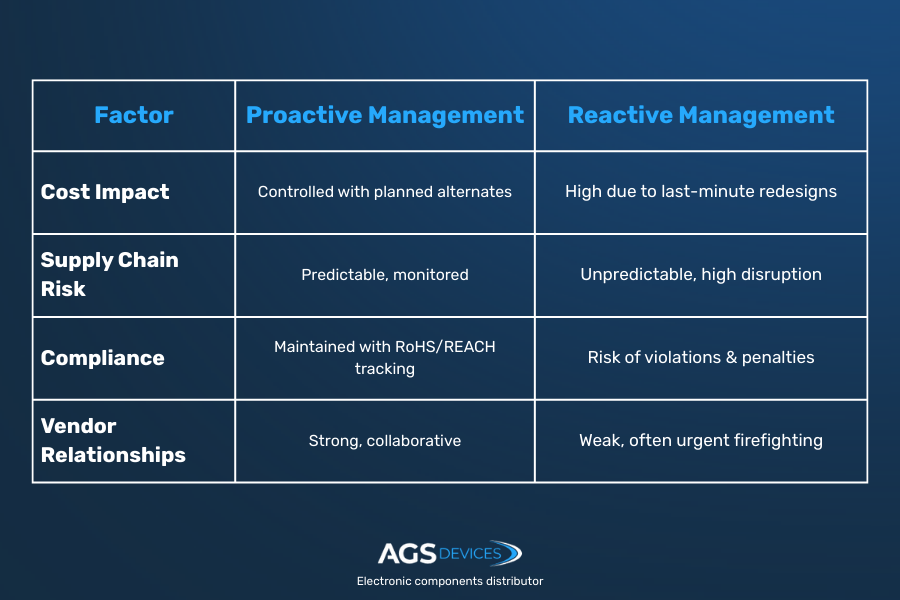

- Avoid last-minute disruptions by identifying lifecycle risks long before they hit your BOM

- Secure supply continuity through early action, like last-time buys or verified alternates

- Maintain regulatory compliance by ensuring parts align with RoHS, REACH, and AVL requirements

- Extend platform viability in sectors where products are expected to run for 10–20+ years

- Reduce dependency on risky secondary markets by managing lifecycle proactively, not reactively

In short, obsolescence management ensures that even as component cycles shrink, your production timeline doesn’t.

How To Build an Effective Obsolescence Management Plan

This section is designed in AGS blog style, commercial in tone, clear in structure, and valuable for manufacturers, OEMs, and supply chain decision-makers.

An effective obsolescence management plan doesn’t just protect you from surprise EOL notices, it gives your supply chain visibility, predictability, and control.

Here’s how to build a plan that actually works:

1. Identify Critical Components Early

Not every part needs the same level of attention.

Focus first on components that are:

- Used in high volumes or across multiple products

- Single-sourced or without verified alternates

- Known to have short lifecycles (e.g., semiconductors, memory ICs)

- Linked to regulated certifications or compliance dependencies

Tip: Build a “critical parts list” that’s updated quarterly and shared across engineering and procurement.

2. Monitor Lifecycle Status Proactively

Stay ahead of End-of-Life (EOL) and Not Recommended for New Design (NRND) alerts with automated tools.

Use resources like:

- Manufacturer product change notifications (PCNs)

- Lifecycle databases (e.g., SiliconExpert, IHS Markit)

- Alerts from authorized distributors or sourcing platforms

Tip: Set up EOL watchlists inside your BOM management software tool for real-time flagging.

3. Define a Cross-Functional Obsolescence Workflow

Everyone from engineering to procurement should be on the same page.

Your workflow should define:

- Who owns lifecycle tracking

- How EOL notifications are evaluated and escalated

- What the fallback options are (last-time buy, alternate sourcing, redesign)

- How risk levels are scored (e.g., impact on compliance, cost, delivery)

Tip: Treat obsolescence like a risk register, assign scores, and review quarterly.

4. Secure Alternate and Replacement Options in Advance

The worst time to look for a replacement part is when your back is against the wall. It pays to have form-fit-function equivalents lined up in advance, so you’re not scrambling when an EOL notice drops into your inbox.

- Identify form-fit-function (FFF) equivalents for each high-risk part

- Validate alternates technically and logistically (spec, pricing, sourcing)

- Align with your Approved Vendor List (AVL) and compliance requirements

Tip: Keep a pre-qualified alternates database so you can pivot fast when needed.

5. Build Supplier Collaboration Into the Process

Too many companies treat suppliers as an afterthought in obsolescence planning. In reality, your best vendors can often see lifecycle changes coming long before you do. A quick heads-up from them can buy you months of breathing room

- Request advanced notice of lifecycle changes

- Ask for help identifying alternates or bridging inventory

- Partner with distributors who specialize in EOL and excess management

Tip: Suppliers that offer excess inventory solutions can help bridge sourcing gaps.

6. Don’t Forget Documentation and Audit Readiness

Obsolescence actions often require compliance reporting, especially in the aerospace, medical, and defense industries.

- Keep a digital log of all EOL notices and responses

- Document alternate validation, sourcing rationale, and risk assessments

- Tie each part’s status to its BOM version history

Tip: This also helps if you ever need to defend lifecycle decisions to regulators or customers.

Best Practices for Handling End-of-Life (EOL) Components

Managing end-of-life parts isn’t just about dodging last-minute headaches. Done right, it builds resilience into your supply chain, so when the unexpected happens, you’ve already got a plan B.

Here are practical, battle-tested best practices that manufacturers, OEMs, and supply chain teams can use to stay ahead of obsolescence:

- Monitor part lifecycle statuses regularly using EOL alerts, manufacturer notices, and BOM manufacturing tracking tools to flag high-risk components early

- Integrate lifecycle insights directly into your BOM so engineers and procurement teams have full visibility on at-risk parts

- Act early on Last Time Buy (LTB) opportunities, especially for high-dependency or long-tail production components

- Forecast long-term demand before purchasing EOL components in bulk, and balance cost savings with shelf-life limitations

- Develop and maintain a pre-approved list of alternates, ensuring they’re validated for form, fit, and function compatibility before they’re urgently needed

- Document all alternate testing and approvals to reduce engineering time when switching components later

- Use vetted suppliers for EOL or constrained inventory, focusing on those that provide traceability, test documentation, and certificates of conformance

Why Choose AGS Devices for Obsolescence Management

When every component counts, you need a sourcing partner that moves fast, sees ahead, and delivers without compromise. AGS Devices is built for that kind of urgency.

Here’s how we help you stay ahead of EOL disruptions:

- Proactive lifecycle monitoring: Identify and flag EOL and NRND components early, before they affect production

- Sourcing of obsolete and constrained components: Tap into our verified global supplier network and excess inventory to locate hard-to-find parts fast

- Alternate and equivalent part matching: Get access to vetted, form-fit-function replacements with proper documentation and compliance assurance

- Obsolescence risk mitigation plans: Avoid last-minute design changes with forward-looking strategies that support your long-term product roadmap

In addition to robust obsolescence management support, we also offer:

Obsolescence Management for Critical Components: FAQs

What is obsolescence management in supply chains?

Obsolescence management is the process of identifying, planning for, and mitigating the risks of parts becoming discontinued or no longer supported. It ensures critical components remain available or are replaced before they disrupt production.

Why do components become obsolete?

Parts typically become obsolete due to manufacturer end-of-life (EOL) notices, declining demand, the release of newer technology, or shifts in the supply chain. In high-tech sectors, lifecycles are often short, making proactive planning essential.

What industries are most affected by obsolescence?

Sectors like aerospace, defense, medical devices, and industrial automation rely on long-life equipment and legacy systems, making them highly vulnerable to EOL disruptions and component shortages.

How can I tell if a component is going to become obsolete?

Manufacturers issue Product Change Notices (PCNs) or End-of-Life (EOL) announcements. BOM audits, lifecycle tracking tools, and sourcing partners, such as AGS Devices, help identify at-risk components early.

What should I do when I receive an EOL notice?

Start sourcing immediately. Options include making a last-time buy, finding an equivalent component (FFF replacement), or revising your BOM with AGS’s support to avoid production delays.

Can AGS help source obsolete or EOL components?

Yes. AGS Devices specializes in sourcing legacy, hard-to-find, and obsolete electronic components through a verified global supplier network. We also provide documentation, testing, and traceability.