Bill of Materials in Supply Chain Management: Key Takeaways

- Most people think of bill of materials as dry technical paperwork, but in the trenches of supply chain ops, they’re the first thing that makes or breaks a product build

- Understanding the difference between engineering BOMs, manufacturing BOMs, and configurable BOMs is key to building scalable and compliant supply chains

- Poorly managed BOMs can lead to obsolete electronic components, mismatched orders, or sourcing delays

- Global supply chains demand dynamic BOM strategies, which include practices like alternate part planning, version tracking, and cross-functional collaboration

- AGS Devices complements your internal tools by offering real-time sourcing, BOM validation, and fast fulfillment support, with compliance documentation included

A single BOM error once cost a manufacturer $23,000 in unusable materials and two weeks of lost production time, all because of a decimal placed in the wrong column.

In an industry where timelines are tight, compliance is strict, and part availability shifts by the hour, the humble BOM is one of the most critical tools in modern supply chain strategy.

If you’re managing a global production run or sourcing components for a prototype, having a clean, structured, and traceable BOM can mean the difference between hitting your deadlines or halting the line.

In this article, we’ll break down:

- What a bill of materials (BOM) is and how it functions in supply chain management

- The different types of BOMs

- Why BOMs are a critical foundation for supply chain efficiency

- Best practices for managing BOMs across global teams, systems, and partners

What Is a BOM in Supply Chain Management?

Think of the BOM as your product’s DNA: it tells everyone what to build, how to source it, and what to expect at every stage.

If your BOM is outdated, missing parts, or scattered across spreadsheets, you can expect sourcing chaos.

Procurement, engineering, and logistics all need to be looking at the same list in real time.

To cover it briefly, a BOM includes:

- Component details: Part numbers, descriptions, specs, quantities

- Supplier/manufacturer info: Who makes or supplies the parts

- Reference designators: Indicate where each part goes in the build

- Revision history: Tracks design changes and versioning

- Compliance data: RoHS, REACH, and lifecycle status (EOL, NRND)

Why BOMs Are Critical in Supply Chain Operations

A structured BOM improves collaboration, reduces delays, and protects against costly errors throughout the procurement and production lifecycle.

It can play a vital role in your supply chain strategy because it:

- Aligns teams across departments: We’ve seen procurement pull parts based on a design that changed weeks ago, leading to entire subassemblies built with obsolete parts. A potential client can lose 3 days of assembly time over this exact issue

- Enables accurate, timely procurement: With precise component details and quantities, BOMs minimize sourcing errors, support alternate part planning, and streamline RFQs with suppliers

- Helps avoid costly delays: BOMs with clear version control and lifecycle tracking reduce the risk of ordering obsolete or incorrect parts, which can stall production lines

- Improves inventory management planning and cost control: When linked with ERP or MRP systems, BOMs allow supply chain teams to forecast better, avoid over-ordering, and consolidate bulk purchases to reduce BOM costs

- Boosts supply chain transparency and traceability: Including manufacturer details, part revisions, and compliance indicators (RoHS, REACH, etc.) supports end-to-end visibility and helps meet regulatory requirements

Types of BOMs in Supply Chain Operations

Different BOM types serve different phases of the product lifecycle, from initial design to fulfillment. Choosing the right one ensures your teams are aligned, your sourcing is accurate, and your production flows smoothly.

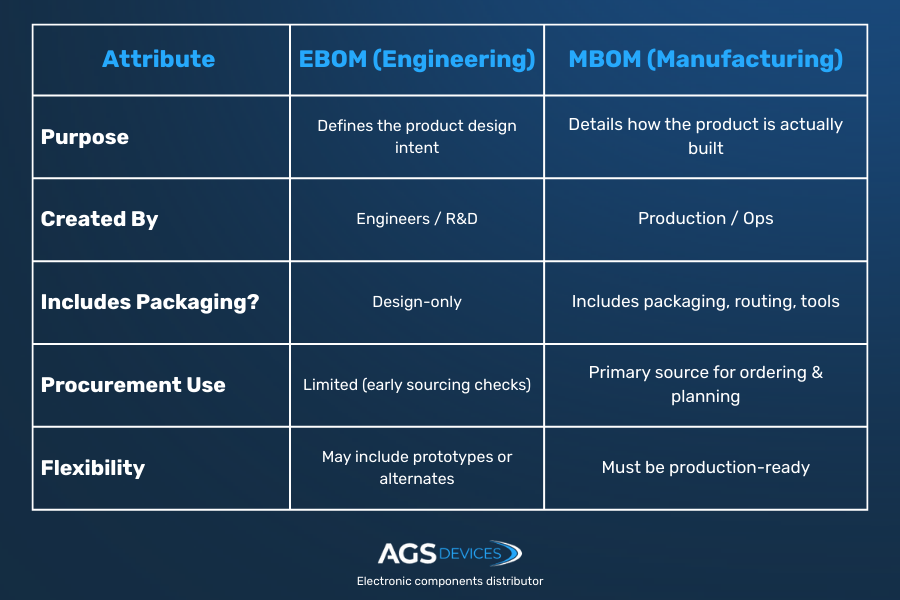

Engineering Bill of Materials (EBOM)

This BOM is created by the engineering or design team during the R&D phase of the product.

It defines the product’s technical foundation and design intent as it:

- Lists all parts and subassemblies based on CAD or design files

- Doesn’t reflect manufacturing sequence or packaging steps

- Often includes prototype or non-production components

- Used to evaluate technical feasibility, part availability, and cost early on

Supply chain relevance: EBOMs provide early visibility into sourcing challenges like long lead times or EOL parts, helping procurement avoid last-minute reengineering.

Manufacturing Bill of Materials (MBOM)

This is where theory meets the factory floor. The MBOM turns your prototype into something that can be really built.

It translates design into executable production steps:

- Includes all parts, tools, and instructions needed for assembly

- Reflects routing, workstations, and packaging materials

- Used directly by ERP and MRP systems for procurement

- Helps define the build cost and labor requirements

Supply chain relevance: MBOMs drive part ordering, warehouse picking, and supplier fulfillment, making them central to accurate inventory and production planning.

If you’d like to compare EBOM vs. MBOM, we have a guide available.

Sales Bill of Materials (SBOM)

If you’ve ever had a customer call asking why a kit arrived missing half the items, it probably started with a sloppy sales BOM.

This list defines what the customer is buying, and it:

- Shows bundled SKUs (kits, pre-configured sets, etc.)

- Doesn’t always correspond 1:1 with inventory structure

- Often lives in CRM or order entry systems

- May include virtual or non-physical components

Supply chain relevance: SBOMs bridge the gap between what’s promised to the customer and what’s shipped, keeping order fulfillment, invoicing, and delivery aligned.

Configurable or Variant BOM (CBOM)

Used when products offer multiple options or modular configurations.

It enables scalable customization without duplicating data:

- Contains logic for including/excluding components based on selections

- Built from a master BOM with conditional rules

- Reduces data redundancy in ERP/PLM systems

- Useful for made-to-order or engineer-to-order workflows

Supply chain relevance: CBOMs support just-in-time sourcing and efficient inventory allocation across variants, reducing overstock and simplifying demand forecasting.

Best Practices for BOM Management in Global Supply Chains

These best practices help future-proof your operations and reduce sourcing and production risks.

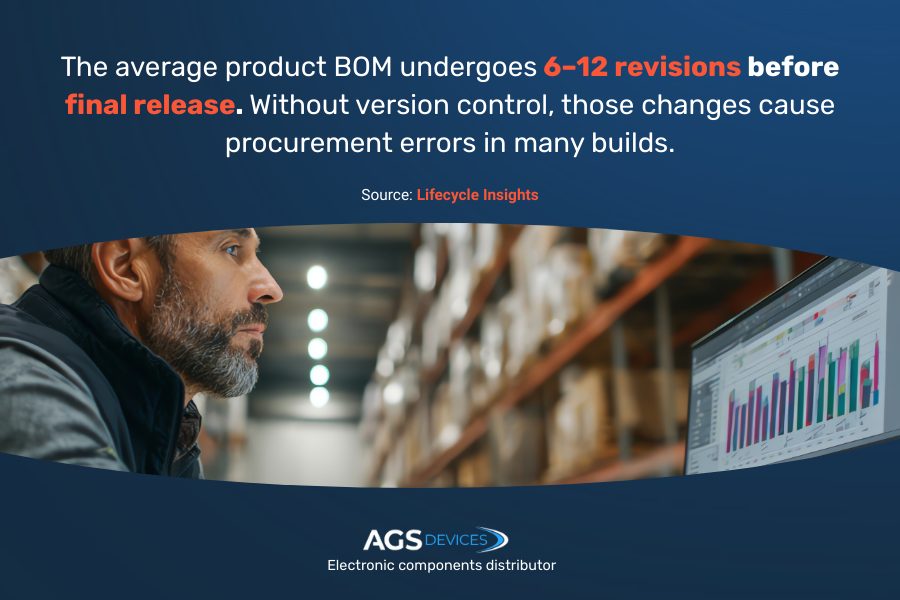

Keep BOMs Dynamic and Version-Controlled

An old BOM is a liability. One wrong version and you’re sending frantic emails to sourcing teams asking if they can just swap in something similar.

- Timestamp every update and change the owner

- Archive older versions for audits and traceability

- Sync updates automatically with engineering and procurement platforms

Standardize BOM Structure Across Regions

Inconsistent data causes errors during global procurement. Unified formatting eliminates miscommunication between teams, suppliers, and ERP systems.

- Use consistent naming conventions and units

- Include universal part descriptions and cross-reference manufacturer numbers

- Ensure multilingual compatibility or annotations if needed

Validate for Accuracy Before Every Upload

A small typo in a part number can cost thousands in sourcing errors or delays. Pre-checks reduce back-and-forth with suppliers.

- Triple-check your BOM for typos as one wrong digit in a part number can cost you days of delay

- Flag duplicates, deprecated components, and invalid quantities

- Cross-check against approved vendor lists (AVLs)

Why AGS Devices Is Your Partner in BOM-Driven Supply Chain Success

If you’re managing production for a prototype or scaling to global volumes, your bill of materials isn’t just a checklist, it’s the blueprint of your success.

At AGS Devices, we help you take control of that blueprint with real-time visibility, structured data, and sourcing support that actually keeps up with your timelines.

We work with supply chain professionals, engineers, and buyers to simplify BOM management and solve the sourcing challenges that slow teams down.

Here’s how AGS Devices supports your BOM strategy:

- BOM management & validation support: Send us your BOM in any format, we’ll cross-reference, flag lifecycle risks, and match to verified sources

- Shortage obsolescence solutions: Avoid production stalls with pre-verified alternates and proactive alerts for EOL or NRND components

- Fast, verified sourcing: Our sourcing engine connects to a global network of suppliers to quote accurate availability and pricing within hours

- Full compliance & documentation: Need RoHS, REACH, or traceability docs? We deliver complete packages with every order to meet quality and regulatory needs

- Dedicated procurement support: Whether it’s a last-minute shortage or a long-term fulfillment plan, our team acts as an extension of yours to keep builds on track

Let’s make your supply chain more resilient, accurate, and efficient, starting with the BOM.

Bill of Materials in Supply Chain Management: FAQs

Still have questions about BOMs and how they impact your supply chain? Here are answers to the ones we hear most often from engineers and procurement teams.

What is the meaning of BOM in supply chain management?

In supply chain management, it serves as a blueprint for procurement, production planning, and inventory control, ensuring the right parts are sourced, stocked, and delivered on time.

Why is a BOM important for procurement and sourcing?

Without an accurate BOM, procurement teams can face delays, duplicate orders, or missed components. A structured BOM allows buyers to source the correct parts, track availability, and align purchasing with production schedules, reducing waste and downtime.

What’s the difference between an Engineering BOM and a Manufacturing BOM?

An Engineering BOM (EBOM) reflects the product design created by R&D, while a Manufacturing BOM (MBOM) includes additional items like packaging, fasteners, or consumables used in production. Both are essential, but serve different functions in the product lifecycle.

How do BOM errors impact supply chain performance?

Even small errors, like outdated part numbers, missing quantities, or unapproved alternates, can cascade into sourcing issues, compliance risks, or stalled production lines. Proper BOM management helps avoid these costly disruptions.

How can BOM management improve product lifecycle planning?

With lifecycle tracking built into your BOM process, you can flag parts approaching end-of-life (EOL), source alternates proactively, and ensure long-term availability for extended product runs. This minimizes redesigns and avoids last-minute sourcing surprises.

Can BOMs be integrated with ERP and inventory systems?

Yes. Modern BOM tools and sourcing platforms (like those supported by AGS Devices) can sync with your ERP or inventory system, enabling real-time updates, smoother procurement workflows, and better forecasting across the supply chain.

What are the best practices for managing BOMs across global teams?

Standardize formats, implement version control, and ensure cross-functional visibility. Use cloud-based BOM software and work with sourcing partners who offer full traceability, compliance documentation, and alternate sourcing support for global needs.