Thermistor vs. Thermocouple: Key Takeaways

- Thermistors provide higher precision at lower temperatures, with typical accuracy ranges of ±0.1°C

- Thermocouples are top performers in extreme heat, withstanding temperatures of up to 2,300°C

- Response time from these two can differ significantly, with thermistors responding in under 1 second in many cases, while thermocouples may take 2–5 seconds depending on insulation and probe type

- Thermistors are affordable but sensitive to stress, while thermocouples are durable and ideal for long-term industrial applications.

- Knowing the trade-offs between range, accuracy, and application environment is important when designing or sourcing temperature-sensing components

Did you know that nearly 50% of sensor selection errors in manufacturing come from misunderstanding the differences between temperature sensor types?

If you’re an engineer, buyer, or technician, you need to know how to choose the right sensor by learning how thermistors and thermocouples work, where they shine, and in which scenarios they work best.

Today we’ll dive into:

- Key differences between thermistors and thermocouples

- How each sensor works and where they’re used

- Pros and cons of thermistors vs thermocouples

- Tips for choosing the right temperature sensor for your use case

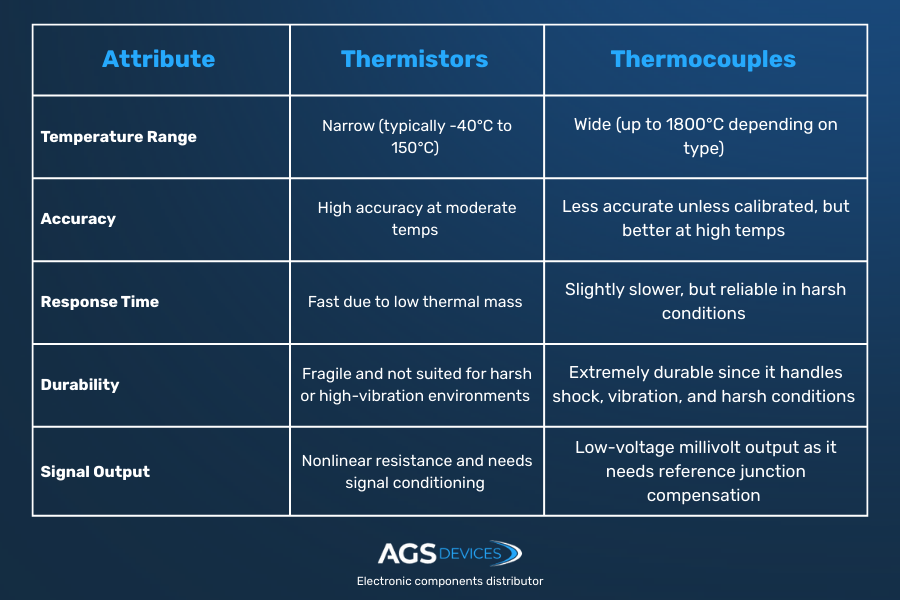

Main Differences When Comparing Thermistors vs. Thermocouples

While both thermistors and thermocouples are temperature sensors, they operate differently and have different applications.

Before diving into their applications, it’s useful to compare their core traits like temperature range, accuracy, response time, durability, and signal output.

Here’s how they compare:

How Thermistors and Thermocouples Work

We already know that they both measure temperature, but their working core principles are fundamentally different.

How Thermistor Sensors Work

Thermistors are temperature-sensitive resistors, and their resistance changes significantly within different ranges of temperature.

This is why they’re the best in use cases such as high-precision measurements within limited temperature ranges.

Thermistors:

- Most commonly use Negative Temperature Coefficient (NTC), where resistance decreases as temperature rises

- Work based on semiconductor materials that respond predictably to temperature fluctuations

- Require an external voltage source to measure the resulting change in resistance

Example: A thermistor embedded in a medical device detects small body temperature shifts by tracking resistance changes.

How Thermocouple Sensors Work

Thermocouples rely on the Seebeck effect; when you join two different metals and heat one end, they generate a tiny voltage that corresponds to the temperature.

They work based on these main characteristics:

- Don’t require an external power source, as they have self-generating sensors

- Voltage output correlates with temperature, which is then interpreted by a thermocouple reader or converter

- Are capable of very high temperature readings, making them ideal for extreme environments

Example: Thermocouples are used in furnaces or jet engines where temperatures go above 1000°C.

Thermocouple vs. Thermistor: Key Factors to Consider

When deciding between a thermistor and a thermocouple, consider your application’s temperature range, accuracy, durability, and cost constraints.

Choose a thermistor if you need:

- High sensitivity at lower temperatures (ideal for ranges under 150°C)

- Fast response times for quick changes in temperature

- Low cost and compact sizing for consumer electronics or wearables

- Applications like HVAC systems, medical devices, or appliances

Choose a thermocouple if you need:

- Wide temperature range support, up to 1800°C or more

- Durability in extreme or high-vibration environments

- Compatibility with industrial machinery, engines, or furnaces

- Long-term reliability in harsh or remote settings

Bonus tip: If your use case requires high accuracy in a moderate range but with better linearity than thermistors, consider a RTD (Resistance Temperature Detector) as a third option.

Starting Costs and Lifecycle

Cost and lifecycle are two of the most important factors when selecting between the two.

Try to keep this in mind when comparing them:

- Upfront cost: Thermistors are usually more affordable, especially for budget-sensitive applications like consumer devices, where sensors are replaced frequently and don’t require extreme durability

- Service life in harsh conditions: Thermocouples are better suited for high-heat or industrial environments. Their rugged design withstands repeated thermal cycling and physical stress, reducing replacement frequency over time

- Budget trade-offs: While thermistors lower initial costs, they may have a shorter service life in demanding settings. Thermocouples cost more upfront but often yield better lifecycle ROI in tough environments

For example:

- Coffee machines often use thermistors that are affordable and precise enough for moderate heat

- Industrial kilns, on the other hand, require thermocouples because they must measure above 1000°C for extended periods.

Accuracy and Temperature Range Differences

Both thermistors and thermocouples measure temperature, but they differ mainly in precision and operating range.

When you’re comparing the two sensors, only a few characteristics make a difference.

Accuracy & Detection

Thermistors offer high sensitivity and are typically more accurate over narrow temperature ranges.

- Ideal for detecting small temperature changes (as small as 0.1°C)

- Commonly used in medical devices, HVAC systems, and consumer electronics

- Accuracy depends on calibration and can degrade outside of their optimal range

Thermocouples provide lower accuracy but are reliable in harsh, high-temperature conditions.

- Tolerances are typically ±1–2°C depending on type and quality

- Accuracy may drift over time without recalibration

- Best suited for applications where extreme conditions are more important than fine precision

Temperature Range

Thermocouples win when it comes to range, as they can measure extreme environments that thermistors can’t handle.

| Sensor Type | Typical Temperature Range |

| Thermistors | -55°C to +150°C (some up to 300°C) |

| Thermocouples | -200°C to +1,800°C (varies by type) |

Applications of Thermocouples vs. Thermistors

Both sensors shine in different environments, so the real question is: where do they get used in the real world?

Common Applications for Thermistors

Thermistors work best in use cases where precision matters in controlled temperature ranges.

Some of these applications include:

- Medical devices (e.g., digital thermometers, incubators)

- HVAC systems (temperature monitoring and feedback)

- Consumer electronics (battery temperature sensing in laptops and smartphones)

- Automotive sensors (coolant and cabin temperature monitoring)

- Home appliances (refrigerators, ovens, washing machines)

Thermistors are ideal for tight tolerance use cases where the smallest temperature changes must be detected quickly.

Common Applications for Thermocouples

Thermocouples are better suited for industrial and high-temperature environments that require rugged sensors and extended range.

- Industrial kilns and furnaces (monitoring temperatures up to 1800°C)

- Power plants and engines (exhaust and combustion monitoring)

- Aerospace and aviation systems (extreme environmental sensing)

- Oil and gas industry (pipeline and drilling equipment monitoring)

- Food processing and packaging (sterilization and cooking control)

Thermocouples earn their place in tough industries because they’re built to survive heat, vibration, and conditions that would destroy other sensors.

Choose Smarter Temperature Sensing With AGS Devices

If you’re developing a precision medical device or engineering for high-heat industrial environments, selecting the right temperature sensor matters.

At AGS Devices, we understand the important role thermistors and thermocouples play in product performance, safety, and compliance.

We also provide electronic components such as:

In addition to robust electronic component products, we also provide:

Not sure which sensor fits your build? Our team at AGS Devices helps engineers every week solve this exact problem.

Thermistor vs. Thermocouple: FAQs

What are usually thermistors used for?

Thermistors are commonly used in low-temperature applications like HVAC systems, medical devices, and consumer electronics for precise and fast-reacting temperature measurement.

What are thermocouples best used for?

Thermocouples are ideal for industrial and high-heat environments like furnaces, engines, and manufacturing processes because of their durability and wide temperature range.

How do thermistors and thermocouples differ?

Thermistors are highly accurate but operate within a narrow temperature range, while thermocouples handle much broader ranges but are slightly less precise.

How do thermistors and thermocouples measure temperature?

Thermistors use resistance changes in response to temperature, while thermocouples generate a voltage from the temperature difference between two dissimilar metals.

Which sensor is more cost-effective in the long run?

Thermistors are cheaper and simpler to use in small devices, while thermocouples cost more but last longer in tough conditions.

Can I use a thermistor instead of a thermocouple?

Use thermistors if your application stays within -50°C to 150°C. For higher heat or industrial environments, switch to thermocouples.

What is a thermistor sensor exactly?

A thermistor is just a resistor that doubles as a thermometer, its resistance changes so predictably with heat that it can be used for precise readings.

Are there different types of thermistors?

Yes. The most common are NTC (Negative Temperature Coefficient), where resistance decreases with rising temperature, and PTC (Positive Temperature Coefficient), where it increases.

What’s more durable: a thermistor or a thermocouple?

Thermocouples are generally more rugged, able to withstand vibration, moisture, and mechanical stress that would quickly damage a thermistor.

Do thermocouples require calibration?

Yes. While thermocouples are durable, they can drift over time and typically require calibration for high-precision applications.