Counterfeit Components: Key Takeaways

- Counterfeit electronic components threaten product reliability, safety, and compliance

- 15% of components sourced through unauthorized channels may be counterfeit, increasing the risk of early failure, non-compliance, and costly product recalls

- The most targeted components include integrated circuits, semiconductors, and capacitor types, many of which are relabeled, cloned, or pulled from scrapped boards

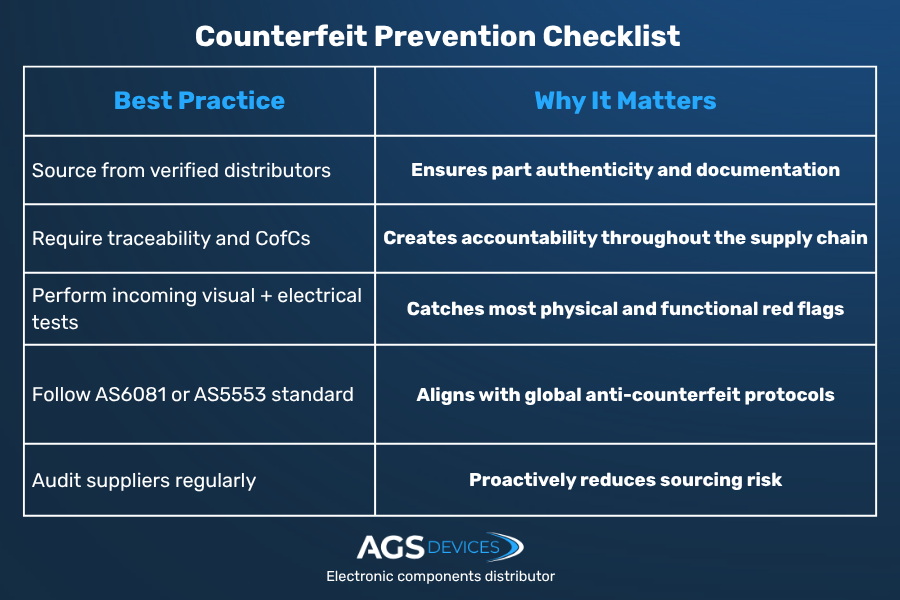

- Effective counterfeit parts prevention requires multi-layered strategies: trusted sourcing, physical testing (e.g., X-ray, electrical), and adherence to standards like AS6081 and IDEA-STD-1010-B

- Even a single counterfeit part can compromise an entire system

An estimated $5 billion in electronic failures each year can be traced back to one source: counterfeit components.

These fake components often look identical to the real product, but when exposed to heat, voltage, or load demands, they fail.

So you can recognize counterfeit components in time, we’ll cover:

- The most common counterfeit components and how they’re disguised

- How fake electronics infiltrate global supply chains

- The real risks they pose to performance, compliance, and safety

- Proven tools and standards for detection and verification

The Growing Threat of Counterfeit Electronic Components

Counterfeit electronic components now impact everything from production schedules to product recalls.

Several converging factors have accelerated the risk:

- Global chip shortages have pushed buyers toward unauthorized or unvetted sources

- End-of-life (EOL) components are increasingly targeted by counterfeiters looking to exploit urgent demand

- Sophisticated cloning techniques now allow fake parts to pass basic visual inspections and function temporarily

- High-risk sectors include aerospace, medical devices, automotive, and industrial automation, where part failure can lead to life-threatening or high-liability outcomes

Common Counterfeit Electronic Components and Their Risks

Certain components are more frequently targeted by counterfeiters due to high value, sourcing difficulty, or legacy demand.

Most common counterfeit parts include:

- Integrated circuits (ICs): Especially microcontrollers, memory chips, and voltage regulators. Often relabeled or harvested from scrap boards

- Transistors and diodes: Small, widely used parts that are easy to repackage and difficult to verify without electrical testing

- Capacitors and resistors: Frequently altered with incorrect values or reconditioned units passed off as new

- Connectors and relays: Often cloned using inferior materials that break down under mechanical or thermal stress

- Power modules and MOSFETs: Falsely labeled with higher ratings to mimic trusted brands in high-current systems

Key risks of using counterfeit components include:

- Early field failures: Fake parts may function initially but degrade rapidly under load or environmental stress

- Overheating and fire hazards: Especially dangerous in power circuits where counterfeit devices can’t manage heat

- Product recalls and warranty exposure: Failures due to unauthorized parts can lead to customer dissatisfaction and loss of reputation

- Non-compliance: Counterfeit parts often lack required certifications like RoHS, REACH, or UL listing

- Intellectual property risks: Cloned parts may infringe on patents, exposing OEMs to legal liabilities

Tools and Programs for Detection and Verification

Manufacturers now rely on multi-layered testing, certifications, and traceability systems to verify authenticity and protect their supply chains.

Here are the most effective tools and programs used across the electronics industry:

1. X-Ray Inspection

This non-destructive method allows inspectors to view internal construction details without opening the package.

Here’s what X-ray testing can detect:

- Die size inconsistencies that don’t match the part spec

- Broken or missing wire bonds inside ICs or relays

- Signs of internal rework or tampering not visible externally

Why it matters: X-rays are highly effective for spotting recycled or altered components, even when external markings are convincing.

2. Decapsulation

By chemically removing the chip casing, inspectors gain access to the actual die, which counterfeiters often try to mask.

This method helps uncover:

- Missing or incorrect manufacturer markings on the die

- Cloned or mismatched internal layouts

- Reused dies packaged in fake or relabeled housings

Keep in mind: Because it’s a destructive method, decapsulation is typically used on suspect samples from high-risk suppliers and not entire lots.

3. Electrical Testing

Even a part that looks authentic can fail under load, electrical testing ensures the component works as expected.

Testing typically covers:

- Voltage, current, and timing parameters

- Switching behavior for transistors and logic ICs

- Performance under temperature or stress conditions

Application tip: Electrical testing is essential for mission-critical builds, especially when sourcing through brokers or during supply chain shortages.

4. Industry Standards

Following industry-approved standards reduces risk and ensures compliance, especially in regulated sectors.

Commonly used frameworks include:

- IDEA-STD-1010-B for visual inspection protocols

- AS6081 for distributor anti-counterfeit procedures

- AS5553 for OEM sourcing and quality control

Worth noting: Aligning with AS5553 or AS6081 not only protects product integrity, it also ensures your sourcing strategy can pass audits in aerospace, defense, and medtech applications.

CTA: Read more about electronic components. Visit Insights.

How Counterfeit Electronic Parts Enter the Supply Chain

Counterfeit electronic parts infiltrate supply chains through multiple weak points, often where oversight is limited or urgency overrides due diligence.

So where do these fakes slip through the cracks?

Common entry points for counterfeit components:

- Unvetted brokers and online marketplaces: Components sold through open exchanges or independent brokers without traceability are among the highest risk

- Excess inventory resales: Genuine parts pulled from scrapped or excess equipment may be relabeled, repackaged, or degraded, yet resold as new

- Re-marking and relabeling: Counterfeiters often reprint labels to inflate specs, hide the part’s age, or mimic a trusted manufacturer

- Incomplete or forged documentation: Lack of certificates of conformance (CofCs) or falsified datasheets can mask part authenticity

- International transshipment: Components may pass through multiple countries to obscure their origin, especially where IP enforcement is weak

- Legacy or EOL parts demand: As certain components become obsolete, counterfeiters fill the gap with clones or relabeled alternatives

How AGS Devices Helps Prevent Counterfeit Risks

At AGS Devices, we understand that counterfeit parts aren’t just a supply issue; they’re a reliability threat.

That’s why we’ve built our sourcing process around traceability, compliance, and rigorous testing.

We support your entire procurement workflow with:

Here’s how we help protect your builds from counterfeit risks:

- Certified sourcing standards: We operate in compliance with ISO 9001 and AS9120, ensuring every supplier is vetted and traceable.

- Third-party and in-house inspections: Components undergo full testing protocols, including X-ray, electrical, and visual inspection, as needed.

- End-to-end traceability: We provide chain-of-custody documentation and full transparency, no gray market shortcuts.

- Lifecycle and shortage support: We help you manage risk across long lead times and EOL transitions without exposing your build to counterfeits.

When failure isn’t an option, AGS Devices delivers parts you can trust every time.

CTA: Need traceable components fast? Let’s connect.

Counterfeit Electronics FAQs

Still have questions about counterfeit electronics? Here are answers to the most common concerns engineers and procurement teams face.

What are counterfeit electronic components, and why are they dangerous?

Counterfeit components are unauthorized or altered parts passed off as legitimate. They pose serious risks including device failure, fire hazards, and regulatory violations. In critical systems, such as aerospace or medical devices, fake electronics can lead to safety failures or recalls.

How do counterfeit electronic parts enter the supply chain?

They often infiltrate through unauthorized resellers, online brokers, or excess inventory sales. A weak counterfeit parts prevention procedure or buying based on cost alone, increases the risk of introducing fake components into your production line.

What is an example of a counterfeit electronic parts issue?

In one notable case, a batch of fake semiconductors made it into a military aircraft. They passed visual checks but failed in the field, and during a heat stress test, several units stopped functioning mid-operation. The incident triggered a costly recall and raised questions about supplier vetting.

How can I spot fake electronics or counterfeit computer chips?

While advanced counterfeits are difficult to detect, common signs include inconsistent markings, poor-quality packaging, mismatched part numbers, or missing documentation. Using a program to identify and track counterfeiters like ERAI or GIDEP that adds another layer of protection.

What’s the most effective counterfeit parts prevention method?

The best approach is a layered one:

- Source only from verified, traceable distributors

- Perform electrical and visual testing

- Follow standards like AS6081 and IDEA-STD-1010-B

- Establish a documented counterfeit prevention policy within your procurement process