BOM in Manufacturing: Key Takeaways

- Over 70% of manufacturers say that real-time BOM visibility improves collaboration and reduces costly mistakes

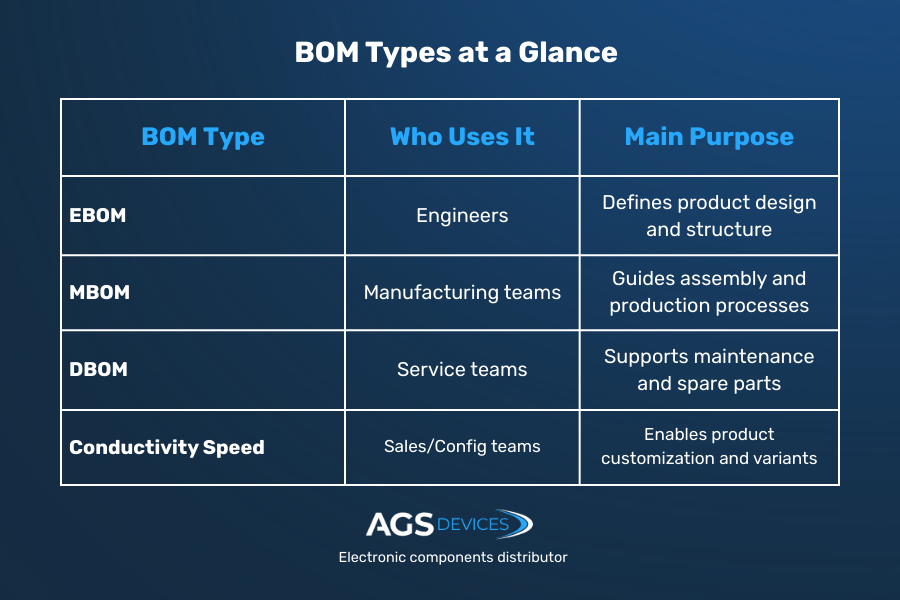

- There are four key BOM types: EBOM, MBOM, SBOM, and CBOM that support different teams across the product lifecycle

- BOMs aren’t just documents; they’re operational systems that tie together design, sourcing, assembly, and compliance

- MBOMs translate engineering intent into shop-floor execution, ensuring production is accurate, efficient, and repeatable

- Well-managed BOMs reduce sourcing delays, inventory errors, and rework costs, directly impacting your bottom line

More than 30% of product delays in manufacturing are traced back to BOM errors.

That’s a staggering stat for something as foundational as a list of parts.

They’re critical tools that drive collaboration, accuracy, and scalability across engineering and operations teams.

In this guide, we break down:

- What a BOM is and how it’s used in real-world workflows

- The differences between EBOMs, MBOMs, SBOMs, and CBOMs

- How to manage BOMs efficiently using modern tools

- And why BOMs are the cornerstone of production, procurement, and compliance

How BOM in Manufacturing Works

A bill of materials (BOM) is the hierarchical blueprint of a product. It outlines every part, from microchips to mechanical fasteners, that’s needed to build and assemble the final unit.

BOMs provide a structured, traceable way to align teams and systems:

- Structured format: Top-level assemblies link to subassemblies and individual components for full traceability

- Flexible delivery: Can be built in spreadsheets, ERPs, or integrated BOM software that syncs with PLM and inventory platforms

- Single source of truth: Ensures design, production, and procurement teams are working from the same dataset

Why BOMs are critical in manufacturing operations:

- Design continuity: Engineers create EBOMs during R&D to capture design intent and support seamless transition to production

- Production accuracy: Operations teams use MBOMs to guide assembly, tooling, and routing instructions, reducing rework and build errors

- Procurement alignment: Sourcing teams rely on BOMs for part validation, sourcing approved MPNs, and managing alternates or lifecycle risks

Types of BOMs in Manufacturing

Understanding the key types helps teams work smarter across design, production, service, and customization.

1. EBOM (Engineering BOM)

The Engineering BOM (EBOM) represents the product as designed by the engineering team. It captures the functional intent of the product, focusing on how the system is meant to work, not how it’s built.

EBOMs are typically created using CAD or PLM systems and include:

- Component specifications

- Part numbers and descriptions

- Reference designators (e.g., R1, C3)

- Firmware and software dependencies (if applicable)

Because EBOMs prioritize design logic over physical assembly, they may include virtual items or placeholders not relevant to manufacturing. As the first formal BOM in the lifecycle, it forms the foundation for all downstream variants.

2. MBOM (Manufacturing BOM)

The manufacturing BOM (MBOM) is the version of the BOM used by operations and production teams.

It details how the product will be physically assembled, including:

- Routing steps and work centers

- Subassemblies and tooling requirements

- Packaging and labeling instructions

- Kit structures for build stations

MBOMs convert design into buildable reality. They eliminate ambiguity by translating engineering intent into manufacturing workflows and are typically managed within MRP or ERP systems.

If you want to know more about these BOMs, check our detailed comparison of EMBOM vs. MBOM.

3. SBOM (Service BOM)

The service BOM (SBOM) defines the product structure from a maintenance and field service perspective.

Common in industries like medical devices, industrial automation, and aerospace, the SBOM supports:

- Spare parts planning

- Warranty and repair processes

- Post-market compliance and documentation

SBOMs ensure service teams can replace parts accurately without needing full design or production documentation.

4. CBOM (Configurable BOM)

A configurable BOM (CBOM) supports mass customization, allowing manufacturers to generate product variations from a single master structure.

CBOMs are used in:

- Modular electronics (e.g., power supplies, robotics)

- Custom medical equipment

- Industrial control panels with variable specs

This flexibility enables manufacturers to scale customized production without maintaining separate BOMs for every product permutation.

How BOMs Are Used in Manufacturing

From design to delivery, BOMs serve as the operational link between teams, driving accuracy, efficiency, and traceability at every stage of manufacturing.

Stakeholders and Use Cases

A BOM isn’t just a technical document; it’s a cross-functional alignment tool used across engineering, production, sourcing, and compliance.

Here’s how each team uses it:

- Engineers: Use EBOMs to define product structure during design, capturing part functions, placement, and technical specs. These are managed in CAD/PLM tools and refined through design iterations.

- Operations: Use MBOMs to guide shop floor execution, covering assembly steps, tools, routing, and packaging. Accurate MBOMs prevent misbuilds and reduce production inefficiencies.

- Procurement: Reference BOMs to source exact parts using manufacturer part numbers and alternates. They streamline RFQs, prevent supply issues, and align sourcing to approved specs.

- Quality teams: Rely on BOMs for traceability, compliance, and audits. BOMs track part origin and usage, supporting standards like ISO, RoHS, and FDA across product revisions.

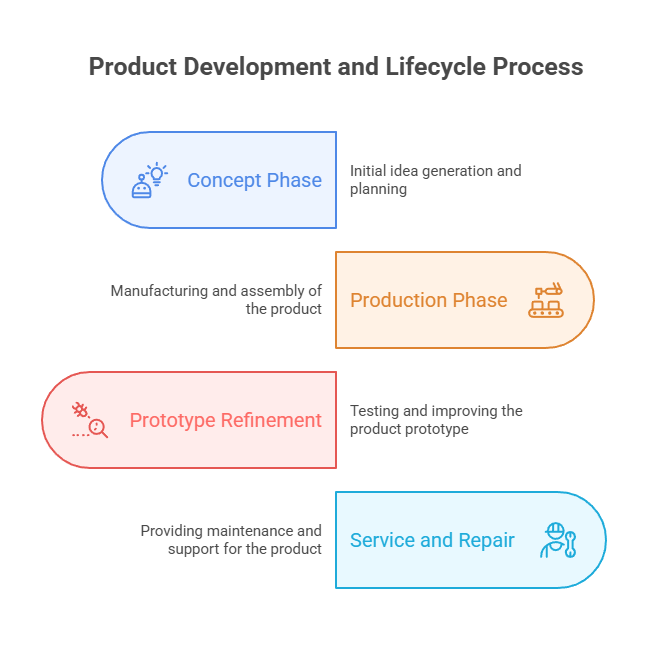

Lifecycle Phases

BOMs evolve alongside the product lifecycle, serving different needs at each stage:

- Concept: Early EBOMs outline theoretical builds and are often incomplete. They guide feasibility studies and cost estimation.

- Prototype: BOMs are refined when parts are sourced and builds are tested. Revisions are tracked closely during this phase.

- Production: Finalized MBOMs are pushed into ERP systems to drive procurement, assembly, and logistics.

- Service and repair: Service BOMs (SBOMs) document which parts are replaceable and how products are disassembled or maintained post-sale.

A well-managed BOM ensures consistency from idea to implementation, keeping every team in sync and every product traceable, repairable, and compliant.

From BOM Accuracy to Supply Chain Agility: AGS Devices Has You Covered

The BOM is your manufacturing blueprint, and when built right, it becomes a force multiplier for speed, accuracy, and resilience.

From aligning design intent with physical execution to preventing sourcing issues and regulatory risk, BOMs are at the heart of high-performance operations.

In addition to robust BOM support, we provide:

Whether you’re scaling production or troubleshooting a high-mix assembly, AGS Devices provide the precision, tools, and expertise to keep your builds on track.

FAQs About BOM Manufacturing

What does BOM stand for in manufacturing?

BOM stands for bill of materials, a comprehensive list of parts, assemblies, subassemblies, and documentation required to build a product. It acts as the single source of truth across engineering, procurement, and production.

What are the main types of BOMs used in manufacturing?

Manufacturing commonly involves four types of BOMs:

- EBOM: Engineering BOM, used during product design

- MBOM: Manufacturing BOM, used for assembly and production

- SBOM: Service BOM, used for repair and maintenance

- CBOM: Configurable BOM, used in mass customization scenarios

Each serves a different phase of the product lifecycle and audience.

How do BOMs support production planning?

BOMs feed directly into MRP (Material Requirements Planning) and ERP systems, enabling:

- Accurate demand forecasting

- Inventory control

- Scheduling of assembly operations

- Procurement and supplier coordination

Well-managed BOMs reduce misbuilds, delays, and overordering.

What software is best for BOM management?

Look for platforms that offer:

- Multi-level BOM support

- Version control and revision tracking

- Integration with ERP, PLM, and inventory systems

- Lifecycle and sourcing alerts

How can I prevent BOM-related delays or mistakes?

- Use dedicated BOM management tools

- Validate component lifecycles and sourcing status

- Keep engineering and manufacturing BOMs synced

- Work with a sourcing partner for proactive support